Page 314 - Air pollution and greenhouse gases from basic concepts to engineering applications for air emission control

P. 314

10.3 Flue Gas Desulfurization 291

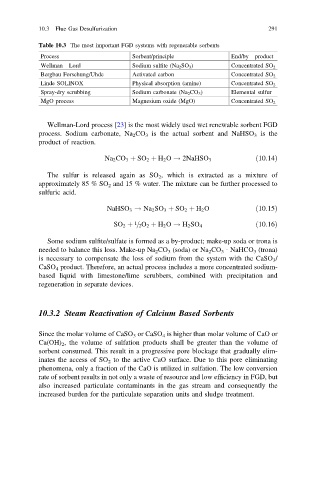

Table 10.3 The most important FGD systems with regenerable sorbents

Process Sorbent/principle End/by—product

Wellman—Lord Sodium sulfite (Na 2 SO 3 ) Concentrated SO 2

Bergbau Forschung/Uhde Activated carbon Concentrated SO 2

Linde SOLINOX Physical absorption (amine) Concentrated SO 2

Spray-dry scrubbing Sodium carbonate (Na 2 CO 3 ) Elemental sulfur

MgO process Magnesium oxide (MgO) Concentrated SO 2

Wellman-Lord process [23] is the most widely used wet renewable sorbent FGD

process. Sodium carbonate, Na 2 CO 3 is the actual sorbent and NaHSO 3 is the

product of reaction.

Na 2 CO 3 þ SO 2 þ H 2 O ! 2NaHSO 3 ð10:14Þ

The sulfur is released again as SO 2 , which is extracted as a mixture of

approximately 85 % SO 2 and 15 % water. The mixture can be further processed to

sulfuric acid.

NaHSO 3 ! Na 2 SO 3 þ SO 2 þ H 2 O ð10:15Þ

1

SO 2 þ = 2O 2 þ H 2 O ! H 2 SO 4 ð10:16Þ

Some sodium sulfite/sulfate is formed as a by-product; make-up soda or trona is

needed to balance this loss. Make-up Na 2 CO 3 (soda) or Na 2 CO 3 · NaHCO 3 (trona)

is necessary to compensate the loss of sodium from the system with the CaSO 3 /

CaSO 4 product. Therefore, an actual process includes a more concentrated sodium-

based liquid with limestone/lime scrubbers, combined with precipitation and

regeneration in separate devices.

10.3.2 Steam Reactivation of Calcium Based Sorbents

Since the molar volume of CaSO 3 or CaSO 4 is higher than molar volume of CaO or

Ca(OH) 2 , the volume of sulfation products shall be greater than the volume of

sorbent consumed. This result in a progressive pore blockage that gradually elim-

inates the access of SO 2 to the active CaO surface. Due to this pore eliminating

phenomena, only a fraction of the CaO is utilized in sulfation. The low conversion

rate of sorbent results in not only a waste of resource and low efficiency in FGD, but

also increased particulate contaminants in the gas stream and consequently the

increased burden for the particulate separation units and sludge treatment.