Page 121 - Air and Gas Drilling Manual

P. 121

Chapter 4: Compressors 4-7

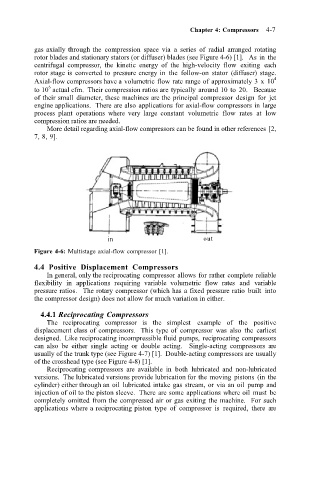

gas axially through the compression space via a series of radial arranged rotating

rotor blades and stationary stators (or diffuser) blades (see Figure 4-6) [1]. As in the

centrifugal compressor, the kinetic energy of the high-velocity flow exiting each

rotor stage is converted to pressure energy in the follow-on stator (diffuser) stage.

Axial-flow compressors have a volumetric flow rate range of approximately 3 x 10 4

6

to 10 actual cfm. Their compression ratios are typically around 10 to 20. Because

of their small diameter, these machines are the principal compressor design for jet

engine applications. There are also applications for axial-flow compressors in large

process plant operations where very large constant volumetric flow rates at low

compression ratios are needed.

More detail regarding axial-flow compressors can be found in other references [2,

7, 8, 9].

in out

Figure 4-6: Multistage axial-flow compressor [1].

4.4 Positive Displacement Compressors

In general, only the reciprocating compressor allows for rather complete reliable

flexibility in applications requiring variable volumetric flow rates and variable

pressure ratios. The rotary compressor (which has a fixed pressure ratio built into

the compressor design) does not allow for much variation in either.

4.4.1 Reciprocating Compressors

The reciprocating compressor is the simplest example of the positive

displacement class of compressors. This type of compressor was also the earliest

designed. Like reciprocating incompressible fluid pumps, reciprocating compressors

can also be either single acting or double acting. Single-acting compressors are

usually of the trunk type (see Figure 4-7) [1]. Double-acting compressors are usually

of the crosshead type (see Figure 4-8) [1].

Reciprocating compressors are available in both lubricated and non-lubricated

versions. The lubricated versions provide lubrication for the moving pistons (in the

cylinder) either through an oil lubricated intake gas stream, or via an oil pump and

injection of oil to the piston sleeve. There are some applications where oil must be

completely omitted from the compressed air or gas exiting the machine. For such

applications where a reciprocating piston type of compressor is required, there are