Page 129 - Air and Gas Drilling Manual

P. 129

maximum pressure capability of the compressor). The disadvantages are: 1) bulky,

2) high initial capital costs (relative to the rotary compressor of similar capabilities)

and, 3) relatively high maintenance costs due to greater number of moving parts

(relative to most rotary compressors). Chapter 4: Compressors 4-15

The main advantages of rotary compressors are: 1) initial low capital cost

(relative to reciprocating compressors), 2) less bulky (relative to the reciprocating

compressors of similar capabilities) and, 3) general ease of maintenance since these

compressors have few moving parts. The main disadvantages are: 1) cannot adjust

to flow line back pressures (fixed compression ratios), 2) needs frequent specific

maintenance of rotating wear surfaces to prevent slippage and, 3) most rotary

compressors operate with oil lubrication in the compression chambers [1, 2, 7].

4.5 Compressor Shaft Power Requirements

The most important single factor affecting the successful outcome of air and gas

drilling operations is the availability of constant, reliable volumetric flow rates of air

or gas to the well. This must be the case even when there are significant (and

frequent) changes in back pressure during these operations. The only two

compressor subclasses that can meet these flexibility requirements are the

reciprocating compressor and the rotary compressor. In what follows, the important

calculation techniques that allow for the proper evaluation and selection of the

appropriate compressors for air and gas drilling operations are reviewed [1, 7 and

10]. This section derives the theoretical power required at the compressor shaft to

compress the gas in the compressor.

4.5.1 Basic Single-Stage Shaft Power Requirement

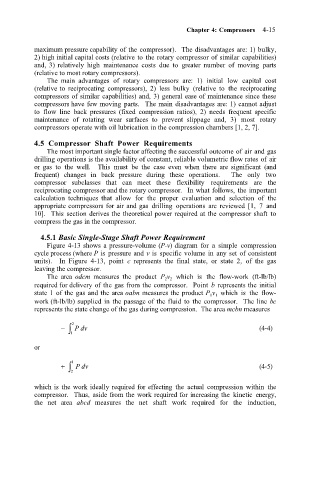

Figure 4-13 shows a pressure-volume (P-v) diagram for a simple compression

cycle process (where P is pressure and v is specific volume in any set of consistent

units). In Figure 4-13, point c represents the final state, or state 2, of the gas

leaving the compressor.

The area odcm measures the product P 2 v 2 which is the flow-work (ft-lb/lb)

required for delivery of the gas from the compressor. Point b represents the initial

state 1 of the gas and the area oabn measures the product P 1 v 1 which is the flow-

work (ft-lb/lb) supplied in the passage of the fluid to the compressor. The line bc

represents the state change of the gas during compression. The area mcbn measures

− 2 Pdv (4-4)

∫ 1

or

+ 1 Pdv (4-5)

∫ 2

which is the work ideally required for effecting the actual compression within the

compressor. Thus, aside from the work required for increasing the kinetic energy,

the net area abcd measures the net shaft work required for the induction,