Page 384 - Air and Gas Drilling Manual

P. 384

Chapter 8: Air, Gas, and Unstable Foam Drilling 8-67

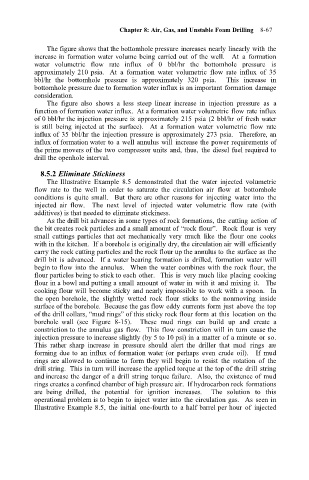

The figure shows that the bottomhole pressure increases nearly linearly with the

increase in formation water volume being carried out of the well. At a formation

water volumetric flow rate influx of 0 bbl/hr the bottomhole pressure is

approximately 210 psia. At a formation water volumetric flow rate influx of 35

bbl/hr the bottomhole pressure is approximately 320 psia. This increase in

bottomhole pressure due to formation water influx is an important formation damage

consideration.

The figure also shows a less steep linear increase in injection pressure as a

function of formation water influx. At a formation water volumetric flow rate influx

of 0 bbl/hr the injection pressure is approximately 215 psia (2 bbl/hr of fresh water

is still being injected at the surface). At a formation water volumetric flow rate

influx of 35 bbl/hr the injection pressure is approximately 273 psia. Therefore, an

influx of formation water to a well annulus will increase the power requirements of

the prime movers of the two compressor units and, thus, the diesel fuel required to

drill the openhole interval.

8.5.2 Eliminate Stickiness

The Illustrative Example 8.5 demonstrated that the water injected volumetric

flow rate to the well in order to saturate the circulation air flow at bottomhole

conditions is quite small. But there are other reasons for injecting water into the

injected air flow. The next level of injected water volumetric flow rate (with

additives) is that needed to eliminate stickiness.

As the drill bit advances in some types of rock formations, the cutting action of

the bit creates rock particles and a small amount of “rock flour”. Rock flour is very

small cuttings particles that act mechanically very much like the flour one cooks

with in the kitchen. If a borehole is originally dry, the circulation air will efficiently

carry the rock cutting particles and the rock flour up the annulus to the surface as the

drill bit is advanced. If a water bearing formation is drilled, formation water will

begin to flow into the annulus. When the water combines with the rock flour, the

flour particles being to stick to each other. This is very much like placing cooking

flour in a bowl and putting a small amount of water in with it and mixing it. The

cooking flour will become sticky and nearly impossible to work with a spoon. In

the open borehole, the slightly wetted rock flour sticks to the nonmoving inside

surface of the borehole. Because the gas flow eddy currents form just above the top

of the drill collars, “mud rings” of this sticky rock flour form at this location on the

borehole wall (see Figure 8-15). These mud rings can build up and create a

constriction to the annulus gas flow. This flow constriction will in turn cause the

injection pressure to increase slightly (by 5 to 10 psi) in a matter of a minute or so.

This rather sharp increase in pressure should alert the driller that mud rings are

forming due to an influx of formation water (or perhaps even crude oil). If mud

rings are allowed to continue to form they will begin to resist the rotation of the

drill string. This in turn will increase the applied torque at the top of the drill string

and increase the danger of a drill string torque failure. Also, the existence of mud

rings creates a confined chamber of high pressure air. If hydrocarbon rock formations

are being drilled, the potential for ignition increases. The solution to this

operational problem is to begin to inject water into the circulation gas. As seen in

Illustrative Example 8.5, the initial one-fourth to a half barrel per hour of injected