Page 385 - Air and Gas Drilling Manual

P. 385

8-68 Air and Gas Drilling Manual

water will be used to saturate the drilling gas with water vapor. Additional injected

water is needed to reduce the stickiness (in much the same way the cooking flour

stickiness is reduced by adding more water). The amount of water added to

eliminate the mud ring stickiness must be determined experimentally and will be

somewhat unique for each drilling operation. As seen in Figure 8-14, additional

injected water will increase the bottomhole and injection pressures.

The procedure for eliminating mud rings is as follows:

1. Begin injecting sufficient water to saturate the gas flow with water vapor.

2. Curtail drilling ahead but continue gas circulation.

3. Bring the rotations of the drill string up to about 100 rpm and lift

the drill string up to the top of the drilling mast and lower it several

times. This will allow the drill collars to smash into the mud ring

structures and break them off the borehole wall.

4. Return to drilling ahead.

5. If the mud rings begin to form again (the injection pressure increases

again), increase the water injection flow rate and repeat the above

sequence.

6. Continue the above five steps until the volumetric flow rate of injected

water reduces the stickiness of the rock flour so that the mud rings no

longer form on the open borehole wall.

For the example borehole given in Illustrative Example 8.5, the typical injected

water volumetric flow rate to eliminate rock flour stickiness would be of the order of

approximately 2 to 10 bbl/hr.

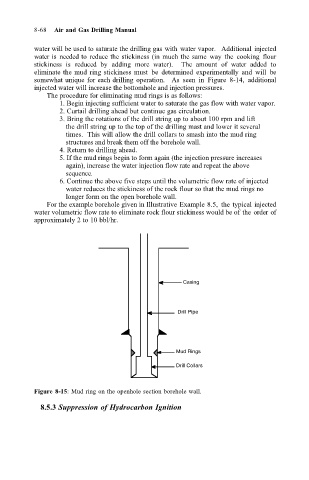

Casing

Drill Pipe

Mud Rings

Drill Collars

Figure 8-15: Mud ring on the openhole section borehole wall.

8.5.3 Suppression of Hydrocarbon Ignition