Page 595 - Air and Gas Drilling Manual

P. 595

Chapter 11: Specialized Drilling Equipment 11-33

MWD system made up above the bent sub. The conventional drill string is made up

to the top of the MWD.

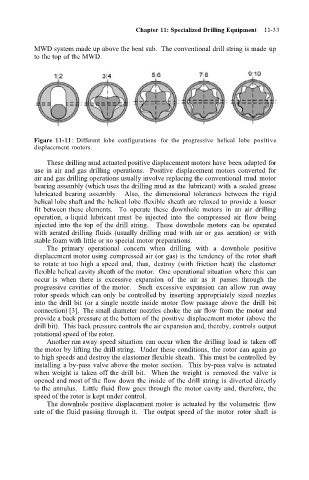

Figure 11-11: Different lobe configurations for the progressive helical lobe positive

displacement motors.

These drilling mud actuated positive displacement motors have been adapted for

use in air and gas drilling operations. Positive displacement motors converted for

air and gas drilling operations usually involve replacing the conventional mud motor

bearing assembly (which uses the drilling mud as the lubricant) with a sealed grease

lubricated bearing assembly. Also, the dimensional tolerances between the rigid

helical lobe shaft and the helical lobe flexible sheath are relaxed to provide a looser

fit between these elements. To operate these downhole motors in an air drilling

operation, a liquid lubricant must be injected into the compressed air flow being

injected into the top of the drill string. These downhole motors can be operated

with aerated drilling fluids (usually drilling mud with air or gas aeration) or with

stable foam with little or no special motor preparations.

The primary operational concern when drilling with a downhole positive

displacement motor using compressed air (or gas) is the tendency of the rotor shaft

to rotate at too high a speed and, thus, destroy (with friction heat) the elastomer

flexible helical cavity sheath of the motor. One operational situation where this can

occur is when there is excessive expansion of the air as it passes through the

progressive cavities of the motor. Such excessive expansion can allow run away

rotor speeds which can only be controlled by inserting appropriately sized nozzles

into the drill bit (or a single nozzle inside motor flow passage above the drill bit

connection) [3]. The small diameter nozzles choke the air flow from the motor and

provide a back pressure at the bottom of the positive displacement motor (above the

drill bit). This back pressure controls the air expansion and, thereby, controls output

rotational speed of the rotor.

Another run away speed situation can occur when the drilling load is taken off

the motor by lifting the drill string. Under these conditions, the rotor can again go

to high speeds and destroy the elastomer flexible sheath. This must be controlled by

installing a by-pass valve above the motor section. This by-pass valve is actuated

when weight is taken off the drill bit. When the weight is removed the valve is

opened and most of the flow down the inside of the drill string is diverted directly

to the annulus. Little fluid flow goes through the motor cavity and, therefore, the

speed of the rotor is kept under control.

The downhole positive displacement motor is actuated by the volumetric flow

rate of the fluid passing through it. The output speed of the motor rotor shaft is