Page 634 - Air and Gas Drilling Manual

P. 634

11-72 Air and Gas Drilling Manual

had a tendency to be damaged and worn by the pipe scale flowing into the sliding

vane cavities of the motor. Due to these problems this early downhole air motor

based on the sliding vane design was abandoned.

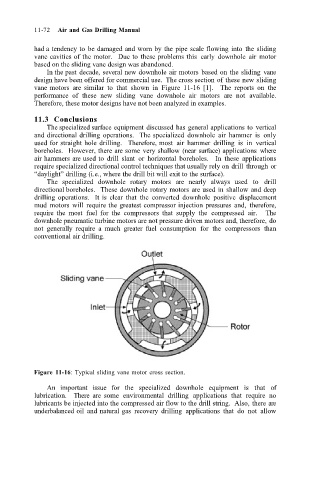

In the past decade, several new downhole air motors based on the sliding vane

design have been offered for commercial use. The cross section of these new sliding

vane motors are similar to that shown in Figure 11-16 [1]. The reports on the

performance of these new sliding vane downhole air motors are not available.

Therefore, these motor designs have not been analyzed in examples.

11.3 Conclusions

The specialized surface equipment discussed has general applications to vertical

and directional drilling operations. The specialized downhole air hammer is only

used for straight hole drilling. Therefore, most air hammer drilling is in vertical

boreholes. However, there are some very shallow (near surface) applications where

air hammers are used to drill slant or horizontal boreholes. In these applications

require specialized directional control techniques that usually rely on drill through or

“daylight” drilling (i.e., where the drill bit will exit to the surface).

The specialized downhole rotary motors are nearly always used to drill

directional boreholes. These downhole rotary motors are used in shallow and deep

drilling operations. It is clear that the converted downhole positive displacement

mud motors will require the greatest compressor injection pressures and, therefore,

require the most fuel for the compressors that supply the compressed air. The

downhole pneumatic turbine motors are not pressure driven motors and, therefore, do

not generally require a much greater fuel consumption for the compressors than

conventional air drilling.

Figure 11-16: Typical sliding vane motor cross section.

An important issue for the specialized downhole equipment is that of

lubrication. There are some environmental drilling applications that require no

lubricants be injected into the compressed air flow to the drill string. Also, there are

underbalanced oil and natural gas recovery drilling applications that do not allow