Page 82 - Air and Gas Drilling Manual

P. 82

3-10 Air and Gas Drilling Manual

sequence of 6 inch, 6 1/8 inch , 6 1/4 inch, 6 1/2 inch, 6 3/4 inch, or the sequence

of 7 1/8 inch, 7 3/8 inch, 7 5/8 inch, and 7 7/8 inch, or the sequence of 8 3/8 inch,

8 1/2 inch, 8 3/4 inch, 9 inch. Using one of these drill bit diameter sequences

allows anticipation of loss of gauge. The top of a long hard abrasive section can be

drilled with a 6 1/2 inch diameter drill bit and when there is a bit change, followed

by a 6 1/4 inch diameter drill bit, and then near the bottom of the section followed

by a 6 1/8 inch diameter drill bit for the last bit change.

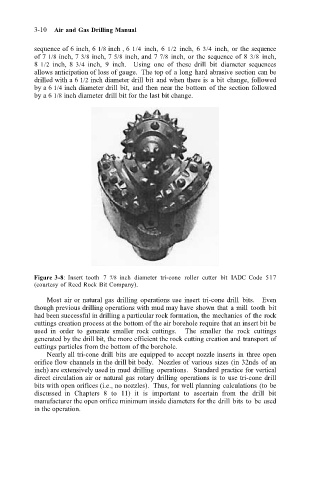

Figure 3-8: Insert tooth 7 7/8 inch diameter tri-cone roller cutter bit IADC Code 517

(courtesy of Reed Rock Bit Company).

Most air or natural gas drilling operations use insert tri-cone drill bits. Even

though previous drilling operations with mud may have shown that a mill tooth bit

had been successful in drilling a particular rock formation, the mechanics of the rock

cuttings creation process at the bottom of the air borehole require that an insert bit be

used in order to generate smaller rock cuttings. The smaller the rock cuttings

generated by the drill bit, the more efficient the rock cutting creation and transport of

cuttings particles from the bottom of the borehole.

Nearly all tri-cone drill bits are equipped to accept nozzle inserts in three open

orifice flow channels in the drill bit body. Nozzles of various sizes (in 32nds of an

inch) are extensively used in mud drilling operations. Standard practice for vertical

direct circulation air or natural gas rotary drilling operations is to use tri-cone drill

bits with open orifices (i.e., no nozzles). Thus, for well planning calculations (to be

discussed in Chapters 8 to 11) it is important to ascertain from the drill bit

manufacturer the open orifice minimum inside diameters for the drill bits to be used

in the operation.