Page 85 - Air and Gas Drilling Manual

P. 85

Chapter 3: Downhole Equipment 3-13

dynamic and is more effective than the quasi-static crushing action of tri-cone and

single cone drill bits. Therefore, air hammer drilling operations require far less

WOB as comparable drilling operations using tri-cone or single cone drill bits.

The air hammer is made up to the bottom of the drill string and at the bottom

of the air hammer is the air hammer bit. The air hammer drill string must be rotated

just like a drill string that utilizes tri-cone or single cone drill bits. The rotation of

the drill string allows the inserts (i.e., tungsten carbide studs) on the bit face to

move to a different location on the rock face surface. This rotation allows a different

position on the rock face to receive the impact load as the upper end of the hammer

bit is struck by the hammer. In direct circulation operations, air flow passes through

the hammer section, through the drill bit channel and orifices to the annulus. As the

air passes into the annulus, the flow entrains the rock cuttings and carries the

cuttings to the surface in the annulus. Direct circulation air hammers are available in

a wide variety of outside housing diameters (3 inches to 16 inches). These air

hammers drill boreholes with diameters from 3 5/8 inches to 17 1/2 inches.

There are also reverse circulation air hammers. These unique air hammers allow

air pressure in the annulus to actuate the hammer via ports in the outside housing of

the hammer. The reverse circulation air hammer bits are designed with two large

orifices in the bit face that allow the return air flow with entrained rock cuttings to

flow to the inside of the drill string and then to the surface. Reverse circulation air

hammers are available in larger outside housing diameters (6 inches to 24 inches).

These air hammers drill boreholes with diameters from 7 7/8 inches to 33 inches.

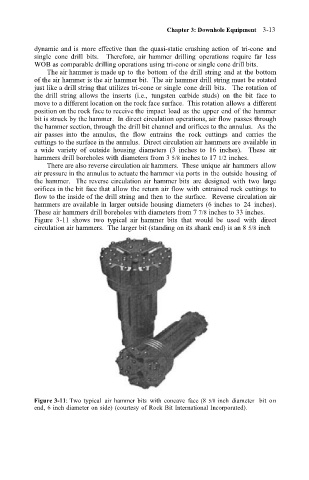

Figure 3-11 shows two typical air hammer bits that would be used with direct

circulation air hammers. The larger bit (standing on its shank end) is an 8 5/8 inch

Figure 3-11: Two typical air hammer bits with concave face (8 5/8 inch diameter bit on

end, 6 inch diameter on side) (courtesy of Rock Bit International Incorporated).