Page 70 - Air and gas Drilling Field Guide 3rd Edition

P. 70

4.1 Rotary Drill String 61

threads). The number of drill pipe joints is determined by the depth of the borehole

to be drilled. Only the drill collars can be placed in compression (to place weight on

the bit). The drill pipe joints are always kept in tension [1].

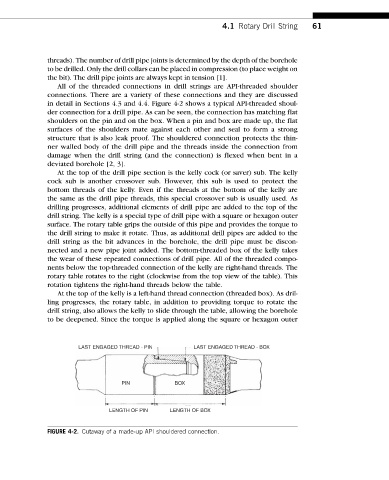

All of the threaded connections in drill strings are API-threaded shoulder

connections. There are a variety of these connections and they are discussed

in detail in Sections 4.3 and 4.4. Figure 4-2 shows a typical API-threaded shoul-

der connection for a drill pipe. As can be seen, the connection has matching flat

shoulders on the pin and on the box. When a pin and box are made up, the flat

surfaces of the shoulders mate against each other and seal to form a strong

structure that is also leak proof. The shouldered connection protects the thin-

ner walled body of the drill pipe and the threads inside the connection from

damage when the drill string (and the connection) is flexed when bent in a

deviated borehole [2, 3].

At the top of the drill pipe section is the kelly cock (or saver) sub. The kelly

cock sub is another crossover sub. However, this sub is used to protect the

bottom threads of the kelly. Even if the threads at the bottom of the kelly are

the same as the drill pipe threads, this special crossover sub is usually used. As

drilling progresses, additional elements of drill pipe are added to the top of the

drill string. The kelly is a special type of drill pipe with a square or hexagon outer

surface. The rotary table grips the outside of this pipe and provides the torque to

the drill string to make it rotate. Thus, as additional drill pipes are added to the

drill string as the bit advances in the borehole, the drill pipe must be discon-

nected and a new pipe joint added. The bottom-threaded box of the kelly takes

the wear of these repeated connections of drill pipe. All of the threaded compo-

nents below the top-threaded connection of the kelly are right-hand threads. The

rotary table rotates to the right (clockwise from the top view of the table). This

rotation tightens the right-hand threads below the table.

At the top of the kelly is a left-hand thread connection (threaded box). As dril-

ling progresses, the rotary table, in addition to providing torque to rotate the

drill string, also allows the kelly to slide through the table, allowing the borehole

to be deepened. Since the torque is applied along the square or hexagon outer

LAST ENGAGED THREAD - PIN LAST ENGAGED THREAD - BOX

PIN BOX

LENGTH OF PIN LENGTH OF BOX

FIGURE 4-2. Cutaway of a made-up API shouldered connection.