Page 98 - An Introduction To Predictive Maintenance

P. 98

88 An Introduction to Predictive Maintenance

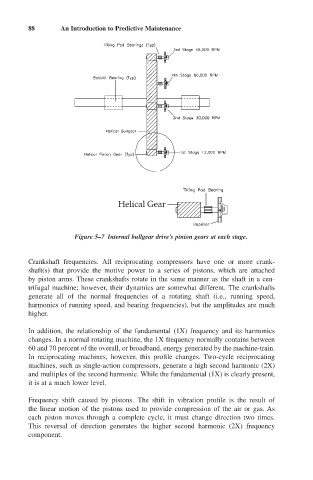

Helical Gear

Figure 5–7 Internal bullgear drive’s pinion gears at each stage.

Crankshaft frequencies. All reciprocating compressors have one or more crank-

shaft(s) that provide the motive power to a series of pistons, which are attached

by piston arms. These crankshafts rotate in the same manner as the shaft in a cen-

trifugal machine; however, their dynamics are somewhat different. The crankshafts

generate all of the normal frequencies of a rotating shaft (i.e., running speed,

harmonics of running speed, and bearing frequencies), but the amplitudes are much

higher.

In addition, the relationship of the fundamental (1X) frequency and its harmonics

changes. In a normal rotating machine, the 1X frequency normally contains between

60 and 70 percent of the overall, or broadband, energy generated by the machine-train.

In reciprocating machines, however, this profile changes. Two-cycle reciprocating

machines, such as single-action compressors, generate a high second harmonic (2X)

and multiples of the second harmonic. While the fundamental (1X) is clearly present,

it is at a much lower level.

Frequency shift caused by pistons. The shift in vibration profile is the result of

the linear motion of the pistons used to provide compression of the air or gas. As

each piston moves through a complete cycle, it must change direction two times.

This reversal of direction generates the higher second harmonic (2X) frequency

component.