Page 109 - Analysis and Design of Machine Elements

P. 109

Detachable Joints and Fastening Methods

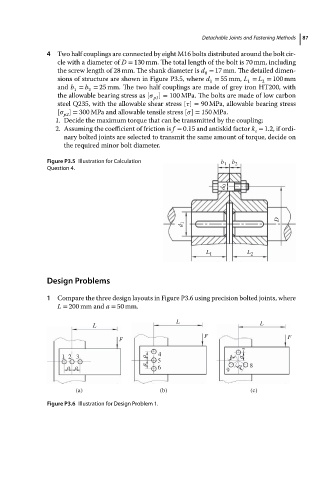

4 Two half couplings are connected by eight M16 bolts distributed around the bolt cir- 87

cle with a diameter of D = 130 mm. The total length of the bolt is 70 mm, including

the screw length of 28 mm. The shank diameter is d = 17 mm. The detailed dimen-

0

sions of structure are shown in Figure P3.5, where d = 55 mm, L = L = 100 mm

1 1 2

and b = b = 25 mm. The two half couplings are made of grey iron HT200, with

1 2

theallowablebearing stress as [ ] = 100 MPa. The bolts are made of low carbon

p1

steel Q235, with the allowable shear stress [ ] = 90 MPa, allowable bearing stress

[ ] = 300 MPa and allowable tensile stress [ ] = 150 MPa.

p2

1. Decide the maximum torque that can be transmitted by the coupling;

2. Assuming the coefficient of friction is f = 0.15 and antiskid factor k = 1.2, if ordi-

s

nary bolted joints are selected to transmit the same amount of torque, decide on

the required minor bolt diameter.

Figure P3.5 Illustration for Calculation b 1 b 2

Question 4.

d 0

D

d 1

L 1 L 2

Design Problems

1 Compare the three design layouts in Figure P3.6 using precision bolted joints, where

L = 200 mm and a = 50 mm.

L

L L

F F

F

7

12 3 aa 5 4 a a

aa 6 9 a 8

(a) (b) (c)

Figure P3.6 Illustration for Design Problem 1.