Page 30 - Analysis and Design of Machine Elements

P. 30

8 Analysis and Design of Machine Elements

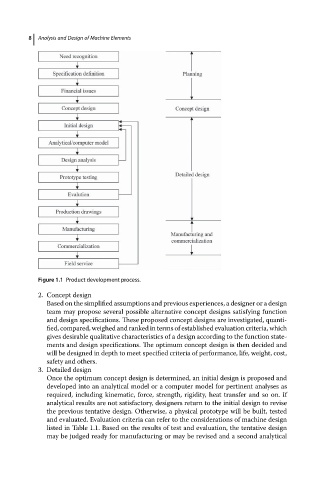

Figure 1.1 Product development process.

2. Concept design

Based on the simplified assumptions and previous experiences, a designer or a design

team may propose several possible alternative concept designs satisfying function

and design specifications. These proposed concept designs are investigated, quanti-

fied, compared, weighed and ranked in terms of established evaluation criteria, which

gives desirable qualitative characteristics of a design according to the function state-

ments and design specifications. The optimum concept design is then decided and

will be designed in depth to meet specified criteria of performance, life, weight, cost,

safety and others.

3. Detailed design

Once the optimum concept design is determined, an initial design is proposed and

developed into an analytical model or a computer model for pertinent analyses as

required, including kinematic, force, strength, rigidity, heat transfer and so on. If

analytical results are not satisfactory, designers return to the initial design to revise

the previous tentative design. Otherwise, a physical prototype will be built, tested

and evaluated. Evaluation criteria can refer to the considerations of machine design

listed in Table 1.1. Based on the results of test and evaluation, the tentative design

may be judged ready for manufacturing or may be revised and a second analytical