Page 316 - Analysis and Design of Machine Elements

P. 316

Analysis and Design of Machine Elements

294

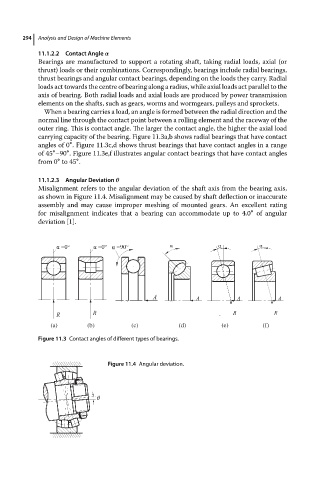

11.1.2.2 Contact Angle

Bearings are manufactured to support a rotating shaft, taking radial loads, axial (or

thrust) loads or their combinations. Correspondingly, bearings include radial bearings,

thrust bearings and angular contact bearings, depending on the loads they carry. Radial

loads act towards the centre of bearing along a radius, while axial loads act parallel to the

axis of bearing. Both radial loads and axial loads are produced by power transmission

elements on the shafts, such as gears, worms and wormgears, pulleys and sprockets.

When a bearing carries a load, an angle is formed between the radial direction and the

normal line through the contact point between a rolling element and the raceway of the

outer ring. This is contact angle. The larger the contact angle, the higher the axial load

carrying capacity of the bearing. Figure 11.3a,b shows radial bearings that have contact

∘

angles of 0 . Figure 11.3c,d shows thrust bearings that have contact angles in a range

∘

∘

of 45 –90 . Figure 11.3e,f illustrates angular contact bearings that have contact angles

∘

∘

from 0 to 45 .

11.1.2.3 Angular Deviation

Misalignment refers to the angular deviation of the shaft axis from the bearing axis,

as shown in Figure 11.4. Misalignment may be caused by shaft deflection or inaccurate

assembly and may cause improper meshing of mounted gears. An excellent rating

∘

for misalignment indicates that a bearing can accommodate up to 4.0 of angular

deviation [1].

(a) (b) (c) (d) (e) (f)

Figure 11.3 Contact angles of different types of bearings.

Figure 11.4 Angular deviation.

θ