Page 315 - Analysis and Design of Machine Elements

P. 315

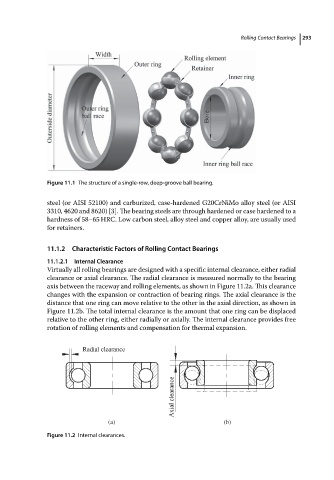

Figure 11.1 The structure of a single-row, deep-groove ball bearing. Rolling Contact Bearings 293

steel (or AISI 52100) and carburized, case-hardened G20CrNiMo alloy steel (or AISI

3310, 4620 and 8620) [3]. The bearing steels are through hardened or case hardened to a

hardness of 58–65 HRC. Low carbon steel, alloy steel and copper alloy, are usually used

for retainers.

11.1.2 Characteristic Factors of Rolling Contact Bearings

11.1.2.1 Internal Clearance

Virtually all rolling bearings are designed with a specific internal clearance, either radial

clearance or axial clearance. The radial clearance is measured normally to the bearing

axis between the raceway and rolling elements, as shown in Figure 11.2a. This clearance

changes with the expansion or contraction of bearing rings. The axial clearance is the

distance that one ring can move relative to the other in the axial direction, as shown in

Figure 11.2b. The total internal clearance is the amount that one ring can be displaced

relative to the other ring, either radially or axially. The internal clearance provides free

rotation of rolling elements and compensation for thermal expansion.

(a) (b)

Figure 11.2 Internal clearances.