Page 310 - Analysis and Design of Machine Elements

P. 310

Analysis and Design of Machine Elements

288

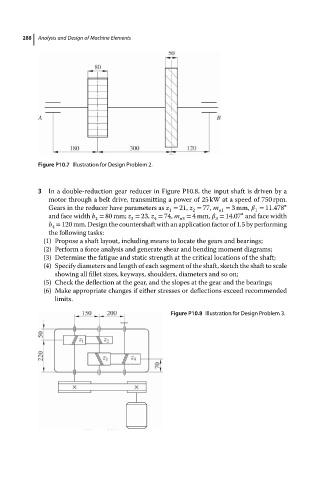

Figure P10.7 Illustration for Design Problem 2.

3 In a double-reduction gear reducer in Figure P10.8, the input shaft is driven by a

motor through a belt drive, transmitting a power of 25 kW at a speed of 750 rpm.

Gears in the reducer have parameters as z = 21, z = 77, m = 3mm, = 11.478 ∘

1 2 n1 1

∘

and face width b = 80 mm; z = 23, z = 74, m = 4mm, = 14.07 and face width

3

2

4

n3

3

b = 120 mm. Design the countershaft with an application factor of 1.5 by performing

4

the following tasks:

(1) Propose a shaft layout, including means to locate the gears and bearings;

(2) Perform a force analysis and generate shear and bending moment diagrams;

(3) Determine the fatigue and static strength at the critical locations of the shaft;

(4) Specify diameters and length of each segment of the shaft, sketch the shaft to scale

showing all fillet sizes, keyways, shoulders, diameters and so on;

(5) Check the deflection at the gear, and the slopes at the gear and the bearings;

(6) Make appropriate changes if either stresses or deflections exceed recommended

limits.

Figure P10.8 Illustration for Design Problem 3.