Page 309 - Analysis and Design of Machine Elements

P. 309

Shafts

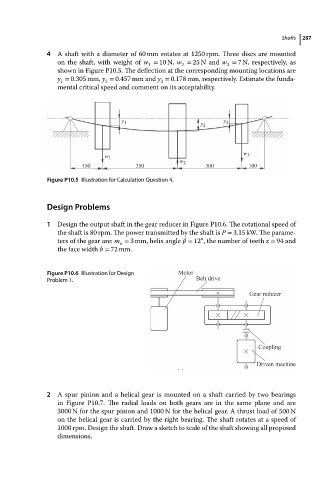

4 A shaft with a diameter of 60 mm rotates at 1250 rpm. Three discs are mounted 287

on the shaft, with weight of w = 10 N, w = 25 N and w = 7N, respectively, as

1

3

2

shown in Figure P10.5. The deflection at the corresponding mounting locations are

y = 0.305 mm, y = 0.457 mm and y = 0.178 mm, respectively. Estimate the funda-

1 2 3

mental critical speed and comment on its acceptability.

y 1 y 3

y 2

w

w 1 3

w 2

150 350 300 100

Figure P10.5 Illustration for Calculation Question 4.

Design Problems

1 Design the output shaft in the gear reducer in Figure P10.6. The rotational speed of

the shaft is 80 rpm. The power transmitted by the shaft is P = 3.15 kW. The parame-

∘

ters of the gear are: m = 3 mm, helix angle = 12 , the number of teeth z = 94 and

n

the face width b = 72 mm.

Figure P10.6 Illustration for Design

Problem 1.

2 A spur pinion and a helical gear is mounted on a shaft carried by two bearings

in Figure P10.7. The radial loads on both gears are in the same plane and are

3000 N for the spur pinion and 1000 N for the helical gear. A thrust load of 500 N

on the helical gear is carried by the right bearing. The shaft rotates at a speed of

1000 rpm. Design the shaft. Draw a sketch to scale of the shaft showing all proposed

dimensions.