Page 400 - Analysis and Design of Machine Elements

P. 400

Analysis and Design of Machine Elements

378

α = 30°~45° α = 2°~8°

α α α α

Figure 13.3 Teeth of jaw clutches.

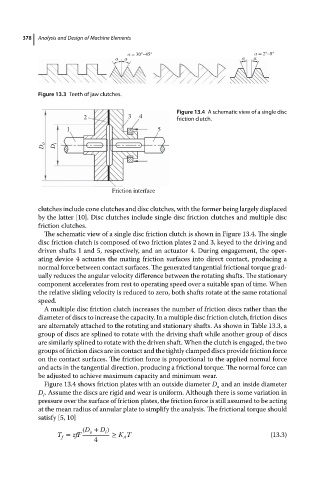

Figure 13.4 A schematic view of a single disc

2 3 4 friction clutch.

1 5

D o D i

Friction interface

clutches include cone clutches and disc clutches, with the former being largely displaced

by the latter [10]. Disc clutches include single disc friction clutches and multiple disc

friction clutches.

The schematic view of a single disc friction clutch is shown in Figure 13.4. The single

disc friction clutch is composed of two friction plates 2 and 3, keyed to the driving and

driven shafts 1 and 5, respectively, and an actuator 4. During engagement, the oper-

ating device 4 actuates the mating friction surfaces into direct contact, producing a

normal force between contact surfaces. The generated tangential frictional torque grad-

ually reduces the angular velocity difference between the rotating shafts. The stationary

component accelerates from rest to operating speed over a suitable span of time. When

the relative sliding velocity is reduced to zero, both shafts rotate at the same rotational

speed.

A multiple disc friction clutch increases the number of friction discs rather than the

diameter of discs to increase the capacity. In a multiple disc friction clutch, friction discs

are alternately attached to the rotating and stationary shafts. As shown in Table 13.3, a

group of discs are splined to rotate with the driving shaft while another group of discs

are similarly splined to rotate with the driven shaft. When the clutch is engaged, the two

groups of friction discs are in contact and the tightly clamped discs provide friction force

on the contact surfaces. The friction force is proportional to the applied normal force

and acts in the tangential direction, producing a frictional torque. The normal force can

be adjusted to achieve maximum capacity and minimum wear.

Figure 13.4 shows friction plates with an outside diameter D and an inside diameter

o

D . Assume the discs are rigid and wear is uniform. Although there is some variation in

i

pressure over the surface of friction plates, the friction force is still assumed to be acting

at the mean radius of annular plate to simplify the analysis. The frictional torque should

satisfy [5, 10]

(D + D )

o

i

T = zfF ≥ K T (13.3)

f

A

4