Page 12 -

P. 12

6 Part I Liquid Drilling Systems

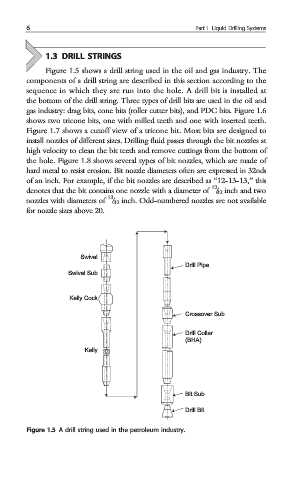

1.3 DRILL STRINGS

Figure 1.5 shows a drill string used in the oil and gas industry. The

components of a drill string are described in this section according to the

sequence in which they are run into the hole. A drill bit is installed at

the bottom of the drill string. Three types of drill bits are used in the oil and

gas industry: drag bits, cone bits (roller cutter bits), and PDC bits. Figure 1.6

shows two tricone bits, one with milled teeth and one with inserted teeth.

Figure 1.7 shows a cutoff view of a tricone bit. Most bits are designed to

install nozzles of different sizes. Drilling fluid passes through the bit nozzles at

high velocity to clean the bit teeth and remove cuttings from the bottom of

the hole. Figure 1.8 shows several types of bit nozzles, which are made of

hard metal to resist erosion. Bit nozzle diameters often are expressed in 32nds

of an inch. For example, if the bit nozzles are described as “12-13-13,” this

12

denotes that the bit contains one nozzle with a diameter of / 32 inch and two

13

nozzles with diameters of / 32 inch. Odd-numbered nozzles are not available

for nozzle sizes above 20.

Swivel

Drill Pipe

Swivel Sub

Kelly Cock

Crossover Sub

Drill Collar

(BHA)

Kelly

Bit Sub

Drill Bit

Figure 1.5 A drill string used in the petroleum industry.