Page 16 -

P. 16

10 Part I Liquid Drilling Systems

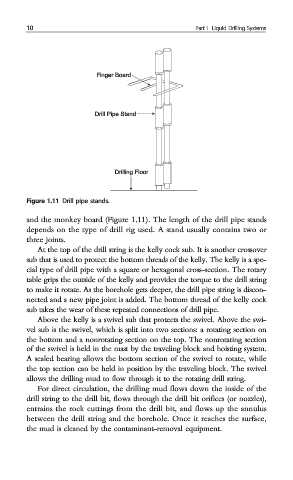

Finger Board

Drill Pipe Stand

Drilling Floor

Figure 1.11 Drill pipe stands.

and the monkey board (Figure 1.11). The length of the drill pipe stands

depends on the type of drill rig used. A stand usually contains two or

three joints.

At the top of the drill string is the kelly cock sub. It is another crossover

sub that is used to protect the bottom threads of the kelly. The kelly is a spe-

cial type of drill pipe with a square or hexagonal cross-section. The rotary

table grips the outside of the kelly and provides the torque to the drill string

to make it rotate. As the borehole gets deeper, the drill pipe string is discon-

nected and a new pipe joint is added. The bottom thread of the kelly cock

sub takes the wear of these repeated connections of drill pipe.

Above the kelly is a swivel sub that protects the swivel. Above the swi-

vel sub is the swivel, which is split into two sections: a rotating section on

the bottom and a nonrotating section on the top. The nonrotating section

of the swivel is held in the mast by the traveling block and hoisting system.

A sealed bearing allows the bottom section of the swivel to rotate, while

the top section can be held in position by the traveling block. The swivel

allows the drilling mud to flow through it to the rotating drill string.

For direct circulation, the drilling mud flows down the inside of the

drill string to the drill bit, flows through the drill bit orifices (or nozzles),

entrains the rock cuttings from the drill bit, and flows up the annulus

between the drill string and the borehole. Once it reaches the surface,

the mud is cleaned by the contaminant-removal equipment.