Page 177 -

P. 177

Gas Compressors 145

Moody, L.F., 1944. Friction factor for pipe flow. Trans. ASME 66, 671–685.

Nikuradse, J., 1933. A new correlation for friction factor. Forschungshelf, 301‒307.

Puon, P.S., Ameri, S., 1984. Simplified approach to air drilling operations. Paper SPE

13380, Proceedings of the SPE Eastern Regional Meeting, Society of Petroleum

Engineers, October 31‒November 2, Charleston.

Schoeppel, R.J., Spare, A.R., 1967. Volume requirements in air drilling. SPE Preprint 1700,

Society of Petroleum Engineers.

Scott, J.O., 1957. How to figure how much air to put down the hole in air drilling. Oil

& Gas J. (December 16), 104–107.

Sharma, M.P., Chowdry, D.V., 1984. A computational model for drilled cutting transport

in air (or gas) drilling operations. Paper 12336, Proceedings of the Southeast Conference

on Theoretical and Applied Mechanics, SPE of AIME.

Sharma, M.P., Crowe, C.T., 1977. A novel physico-computational model for quasi: one-

dimensional gas-particle flows. Trans. ASME 22, 79–83.

Singer, C. et al., 1958a. History of Technology, vol. 4. Oxford Press.

Singer, C. et al., 1958b. History of Technology, vol. 6. Oxford Press.

Supon, S.B., Adewumi, M.A., 1991. An experimental study of the annulus pressure drop

in a simulated air-drilling operation. SPE Drill. Completion J. (September), 74–80.

Tian, S., Adewumi, M.A., 1991. Development of hydrodynamic model-based air drilling

design procedures. Paper SPE 23426, Proceedings of the SPE Eastern Regional

Meeting, Society of Petroleum Engineers, October 22-25.

Weymouth, T.R., 1912. Problems in natural gas engineering. Trans. ASME 34, 185–189.

Wolcott, P.S., Sharma, M.P., 1986. Analysis of air drilling circulating systems with appli-

cation to air volume requirement estimation. Paper SPE 15950, Proceedings of the

SPE Eastern Regional Meeting, Society of Petroleum Engineers, November 12‒14,

Columbus.

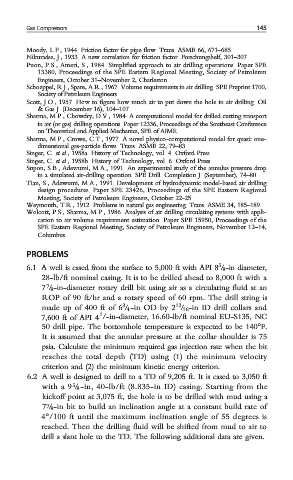

PROBLEMS

5

6.1 A well is cased from the surface to 5,000 ft with API 8 / 8 -in diameter,

28-lb/ft nominal casing. It is to be drilled ahead to 8,000 ft with a

7 7 / 8 -in-diameter rotary drill bit using air as a circulating fluid at an

ROP of 90 ft/hr and a rotary speed of 60 rpm. The drill string is

13

3

made up of 400 ft of 6 / 4 -in OD by 2 / 16 -in ID drill collars and

1

7,600 ft of API 4 /-in-diameter, 16.60-lb/ft nominal EU-S135, NC

50 drill pipe. The bottomhole temperature is expected to be 140°F.

It is assumed that the annular pressure at the collar shoulder is 75

psia. Calculate the minimum required gas injection rate when the bit

reaches the total depth (TD) using (1) the minimum velocity

criterion and (2) the minimum kinetic energy criterion.

6.2 A well is designed to drill to a TD of 9,205 ft. It is cased to 3,050 ft

5

with a 9 / 8 -in, 40-lb/ft (8.835-in ID) casing. Starting from the

kickoff point at 3,075 ft, the hole is to be drilled with mud using a

7 7 / 8 -in bit to build an inclination angle at a constant build rate of

4°/100 ft until the maximum inclination angle of 55 degrees is

reached. Then the drilling fluid will be shifted from mud to air to

drill a slant hole to the TD. The following additional data are given.