Page 94 - Applied Petroleum Geomechanics

P. 94

86 Applied Petroleum Geomechanics

compression tests. Empirical equations and correlations between rock strengths and

petrophysical and geophysical properties are presented for different lithologies. New

correlations for deepwater reservoirs and shale oil and shale gas formations are pro-

posed. These correlations enable one to obtain continuous rock strengths along the

depth interval of interest from well logging and seismic data (e.g., sonic velocity, transit

time, and porosity). Rock failure criteria are examined to reveal rock failure mecha-

nisms, including linear and nonlinear MohreCoulomb, DruckerePrager, true triaxial,

CameClay, and modified Griffith failure criteria. Their suitability and applicability for

geomechanical modeling are also discussed. The anisotropy of rock strengths and its

impact on rock failures are also investigated.

Keywords: Anisotropy; Failure criterion; Laboratory test; Rock strength; Strength

correlation; Well log.

3.1 Laboratory tests for rock strengths

Laboratory tests usually consist of simple experiments appropriate to the nature

of the rock in which important quantities, often stress and strain, are deter-

mined (Jaeger and Cook, 1979). Different types of laboratory tests can be used

to obtain rock strength, Young’s modulus, and other mechanical properties.

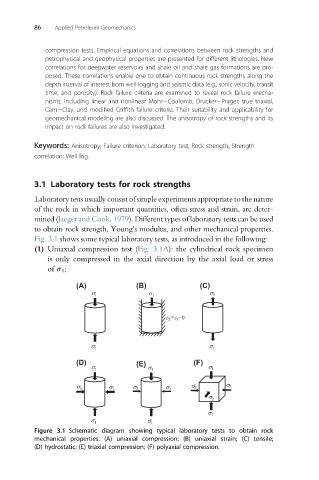

Fig. 3.1 shows some typical laboratory tests, as introduced in the following:

(1) Uniaxial compression test (Fig. 3.1A): the cylindrical rock specimen

is only compressed in the axial direction by the axial load or stress

of s 1 ;

(A) (B) (C)

(D) (E) (F)

Figure 3.1 Schematic diagram showing typical laboratory tests to obtain rock

mechanical properties. (A) uniaxial compression; (B) uniaxial strain; (C) tensile;

(D) hydrostatic; (E) triaxial compression; (F) polyaxial compression.