Page 13 - Applied Process Design For Chemical And Petrochemical Plants Volume II

P. 13

2 Applied Process Design for Chemical and Petrochemical Plants

Overhead Vapor VI YD ,Ha +e

A t' Condenser

- out Pc

",+2 Reflux, L, ~0 = X, +

(Vopor is Distillate, D, , yc = x,,

L, + 3 I Product

I when Partial

Rectifying Section Condenser Used)

xD'xn+3

(Note: This stream does not

exist for partial condenser

system)

Lc = Llquid Condensate

Duty or Lood

am

I-

Reboiler

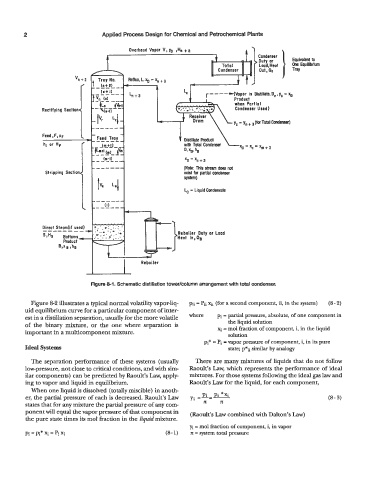

Figure 81. Schematic distillation tower/column arrangement with total condenser.

Figure 8-2 illustrates a typical normal volatility vapor-liq- p~ = Pii qi (for a second component, ii, in the system) (8 - 2)

uid equilibrium curve for a particular component of inter-

est in a distillation separation, usually for the more volatile where pi = partial pressure, absolute, of one component in

of the binary mixture, or the one where separation is the liquid solution

important in a multicomponent mixture. xi = mol fraction of component, i, in the liquid

solution

pi* = Pi 0 vapor pressure of component, i, in its pure

Ideal Systems state; p*ii similar by analogy

The separation performance of these systems (usually There are many mixtures of liquids that do not follow

low-pressure, not close to critical conditions, and with sim- Raoult's Law, which represents the performance of ideal

ilar components) can be predicted by Raoult's Law, apply- mixtures. For those systems following the ideal gas law and

ing to vapor and liquid in equilibrium. Raoult's Law for the liquid, for each component,

When one liquid is dissolved (totally miscible) in anoth- yi ----

er, the partial pressure of each is decreased. Raoult's Law Pi Pi *xi

states that for any mixture the partial pressure of any com- a x

ponent will equal the vapor pressure of that component in (Raoult's Law combined with Dalton's Law)

the pure state times its mol htion in the lipid mixture.

yi = mol fraction of component, i, in vapor

a - system total pressure