Page 113 - Applied Process Design for Chemical and Petrochemical Plants Volume I

P. 113

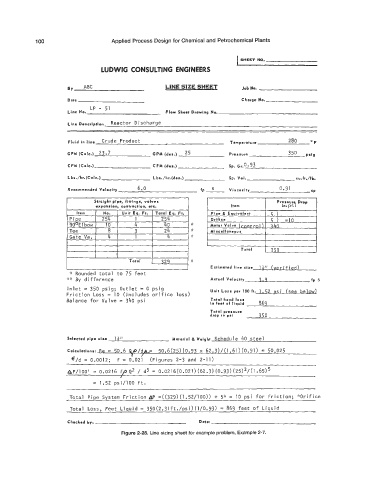

100 Applied Process Design for Chemical and Petrochemical Plants

SHEET NO.

LUDWIG CONSULTING ENGINEERS

BY ABC LINE SIZE SHEET Job No.

Date Charge No.

LP - 51

Line NO. Flow Sheet Drowipg No.

~

~

~i~~ ~ Reactor ~Discharge ~ i ~ ~ i ~ ~

Fluid in line Crude Product Temperature 280 OF

GPM (Calc.) 23.7 GPM (des.) 25 Pres sure 350 psig

CFM (Calc.) CFM (des.) Sp. Gr.O.93 -

L b s . /hr. (C a I c. ) L bs./hr.(des.) sp. VOl. cu.ft./lb.

S

Recommended Velocity 6.0 fP ___ Viscosity 0.91 CP

Straight pipe, fittings, valves Pressure. Drop

expansion, contraction, etc. Item in- pS I

Item No. Unit Eq. Ft. Total Eq. Ft. Pipe B Equivalent 5)

1

Pipe 254 4 254 L Ori fi ce 5 1 =10

s

Mator Valve (control 1 740

40

90OElbow

10

8

3

Tee

24

Mi scellaneaus

4

4

1

Gate Va.

Total i -

1

1

1

I

I

Total

f Rounded total to 75 feet !c Estimated line size erif ied)

By difference Actual Velocity 3.9 fp s

Inlet = 350 psig; Outlet = 0 psig Unit Lass per 100 ft. 1.52 Dsi (see below]

Friction Loss = 10 (includes orifice loss)

Balance for Valve = 340 psi Total head loss 869

in feet of liquid

Total pressure

drop in psi 350

Selected pipe sire 14" Material 8 Weight Schedule 40 steel

Calculations: Re = 50.6 QP/ dL= 50.6(25) (0.93 x 62.3)/(1.61) (0.91) = 50,025

b/d = 0.0012; f = :.02: (Figures 2-3 and 2-11)

AP/lOO' = 0,0216 f/3 Q2 / d5 = 0.0216(0.021) (62.3) (0.93) (25)*/(1.65)5

4

= 1.52 psi/lOO ft.

Total Pipe System Friction =((329)(1.52/100)) + 5" = 10 psi for friction; "Orifice

Total Loss, Feet Liquid = 350(2.3lft./psi)(l/0.93) = 869 feet of Liquid

Checked by: Dote:

Figure 2-28. Line sizing sheet for example problem, Example 2-7.