Page 37 - Applied Process Design for Chemical and Petrochemical Plants Volume I

P. 37

Process Planning, Scheduling and Flowsheet Design 25

C -2 Single compressor in different service (by incineration, vent, and cooling tower waters and number

fluid OT compression ratio) from C-1's above. all like process items within that system, for example:

S - First separator in a process Reactor System, R Reactor is

1

S-2 Second separator in a process Reactor vent cooler is RE-1

S-3a Twoi entical separators connected in Reactor vent condenser is RE-2

S-3b parallel, in same process service. Reactor recycle pu

Level control

Some equipment code systems number all items on Then, establish the same concept for all other unit or

first process flowsheet with 100 series, as C-101, C-102, P- block processing systems. This is often helpful for large

106 to represent compressors number 101 and 102 in dif- projects, such as refinery or grass roots chemical processes.

ferent services and pump 406 as the sixth pump on the Valve identification codes are usually used in prefer-

sheet. The second sheet uses the 200 series, etc. This has ence to placing each valve specification on the flowsheet.

some engineering convenience but is not always clear This latter method is feasible for small systems, and is most

from the process view. workable when a given manufacturer (not necessarily the

same manufacturer for all valves) can be selected and his

To keep process 'continuity clear, it is usually best to

number all like items sequentially throughout the process, valve catalog figure number used on the flowsheet. For

with no concern for which flowsheet they appear on. Also, large jobs, or where many projects are in progress at one

another popular numbering arrangement is to identify a time, it is common practice to establish valve specifications

system such as reaction, drying, separation, purification, for the various process and utility services (see Figures 1-25

and 1-26) by manufacturers' catalog figure numbers.

These are coded as V-11, V-12, V-13, etc., and such code

numbers are used on the flowsheets wherever these valves

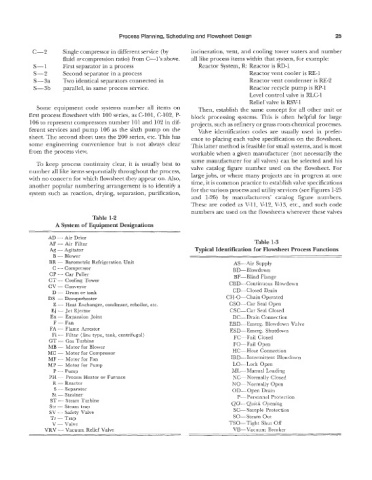

Table 1-2

A System of Equipment Designations

AD - Air Drier

AF- Air Filter Table 1-3

Ag - Agitator Typical Identification for Howsheet Process hnctians

B - Blower

BR - Barometric Refrigeration Unit AS-Air Supply

C - Compressor BD-Blowdown

CP - Car Puller BF-Blind Flange

CT- Cooling Tower CBD-Continuous Blowdown

CV - Conveyor

D - Drum or tank CD-Closed Drain

DS - &superheater CH-0-Chain Operated

E - Heat Exchanger, condenser, reboiler, etc. CSQ-Car Seal Open

Ej - Jet Ejector CSC-Car Seal Closed

Ex- Expansion Joint DC-Drain Connection

F-Fan EBD-Emerg. Blowdown Valve

FA- Flame Arrestor ESD-Emerg. Shutdown

Fi - Filter (line type, tank, centrifugal) FC-Fail Closed

GT - Gas Turbine

MB - Motor for Blower FO-Fail Open

MC - Motor for Compressor HC-Hose Connection

MF - Mctor for Fan IBD- Intermittent Blowdown

MP -- Motor for Pump LO-Lock Open

P - Pump MGManuai Loading

PH - Process Heater or Furnace NC-Normally Closed

R - Reactor. NO- Normally Open

S - Separator OD- Open Drain

St - Strainer P- Personnel Protection

ST - Steam 'Tuibine QO- Quick Opening

Str - Steam trap

SV - Safety Valve SC- Sample Protection

Tr - Trap SO-Steam Out

V - Valve TSO-Tight Shut QfF

VRV - Vacuum Relief Valve VB-Vacuum Breaker