Page 73 - Applied Process Design for Chemical and Petrochemical Plants Volume I

P. 73

60 Applied Process Design for Chemical and Petrochemical Plants

1" - 6" SCH 80

8" - SCH 40 FLANGE 3

MAX 12"--

MAX 120"

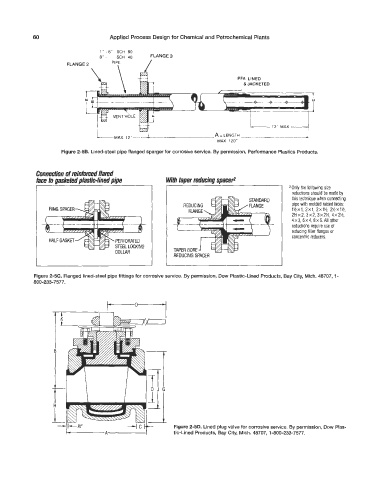

Figure 2-5B. Lined-steel pipe flanged sparger for corrosive service. By permission, Performance Plastics Products.

Connection of reinforced flared

face to flasketed plastiMned pipe Witll taper reducinfl spacer2

2 Only the following size

reductions should be made by

this technique when connecting

pipe with molded raised faces:

l%xl, 2xl,2xlM, 2%x11/2,

21/x2,3~2,3~2%, 4x2%,

4x3, 6x4, 8x6. All other

reductions require use of

reducing filler flanges or

concentric reducers.

COLLAR

REDUCING SPACER

Figure 2-5C. Flanged lined-steel pipe fittings for corrosive service. By permission, Dow Plastic-Lined Products, Bay City, Mich. 48707, 1 -

800-233-7577.

-I I

1

i

Figure 2-5D. Lined plug valve for corrosive service. By permission, Dow Plas-

tic-Lined Products, Bay City, Mich. 48707, 1-800-233-7577.