Page 75 - Applied Process Design for Chemical and Petrochemical Plants Volume I

P. 75

62 Applied Process Design for Chemical and Petrochemical Plants

Orifice flanges are widely used in conjunction with orifice meters for measuring the rate of

flow of liquids and gases. They are basically the same as standard welding neck, slip-on and

screwed flanges except for the provision of radial, tapped holes in the flange ring for meter

connections and additional bolts to act as jack screws to facilitate separating the flanges for

inspection or replacement of the orifice plate.

Blind flanges are used to blank off the ends of piping, valves and pressure vessel openings.

From the standpoint of internal pressure and bolt loading, blind flanges, particularly in the larg-

er sizes, are the most highly stressed of all American Standard flange types; however, since

the maximum stresses in a blind flange are bending stresses at the center, they can safely be

permitted to be higher than in other types of flanges.

1 .) In Tube Turns tests of all types of flanged assemblies, fatigue failure invariably occurred in the pipe or in an unusually weak weld, never in the flange proper.

The type of flange, however, and particularly the method of attachment, greatly influence the number of cycles required to cause fracture.

2.) ANSI 61 6.5-1 961 -Steel Pipe Flanges and Flanged Fittings.

3.) ASME Boiler and Pressure Vessel Code 1966, Section I, Par. P-300.

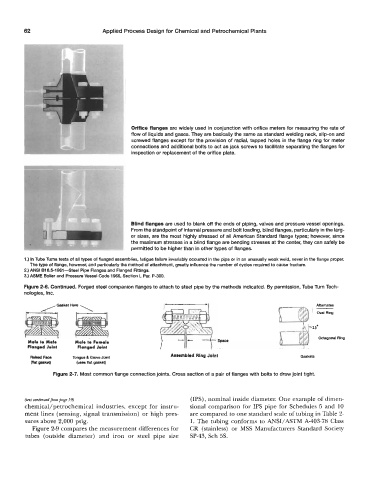

Figure 2-6. Continued. Forged steel companion flanges to attach to steel pipe by the methods indicated. By permission, Tube Turn Tech-

nologies, Inc.

Malo to Malo Malo to Fomalo ) -11- Ring

Flongod Joint Flangod Joint fswe

As~mblod Ring Joint

Raked Face Tongue EL Grove Joint Gaskets

mgssket) (uses flat gasket)

Figure 2-7. Most common flange connection joints. Cross section of a pair of flanges with bolts to draw joint tight.

(kxt continued fiMn page 59) (IPS), nominal inside diameter. One example of dimen-

chemical/petrochemical industries, except for instru- sional comparison for IPS pipe for Schedules 5 and 10

ment lines (sensing, signal transmission) or high pres- are compared to one standard scale of tubing in Table 2-

sures above 2,000 psig. 1. The tubing conforms to ANSI/MTM A-403-78 Class

Figure 2-9 compares the measurement differences for CR (stainless) or MSS Manufacturers Standard Society

tubes (outside diameter) and iron or steel pipe size SP-43, Sch 5s.