Page 97 - Applied Process Design for Chemical and Petrochemical Plants Volume I

P. 97

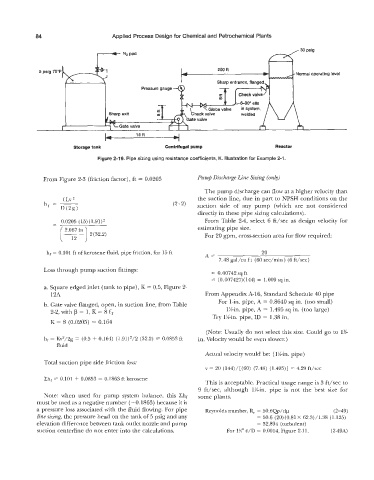

84 Applied Process Design for Chemical and Petrochemical Plants

30 psig

I-+ d

I N2pad 1 I

5 psig 70’F-l 200 ft Noi mal operating level

Pressure gauge

c T

Sharp exit a

15R

Storage tank Centrifugal pump Reactor

Figure 2-19. Pipe sizing using resistance coefficients, K. Illustration for Example 2-1.

From Figure 2-3 (friction factor), ft = 0.0205 Pump Discharge Line Sizing (only)

The pump discharge can flow at a higher velocity than

the suction line, due in part to NPSH conditions on the

(2- 2) suction side of any pump (which are not considered

directly in these pipe sizing calculations).

(T) estimating pipe size.

- 0.0205 (15) (l.91)z From Table 2-4, select 6 ft/sec as design velocity for

2(32.2)

For 20 gpm, cross-section area for flow required:

hf = 0.101 ft of kerosene fluid, pipe friction, for 15 ft A= 20

7.48 gal/cu f t (60 sec/min ) (6 ft/sec)

Loss through pump suction fittings: = 0.00742 sq ft

= (0.007427)(144) = 1.009 sq in.

a. Square edged inlet (tank to pipe), K = 0.5, Figure 2-

12A From Appendix A-16, Standard Schedule 40 pipe

For 1-in. pipe, A = 0.8640 sq in. (too small)

b. Gate valve flanged, open, in suction line, from Table 1%-in. pipe, A = 1.495 sq in. (too large)

2-2, With p = 1, K = 8 fT

Try 1X-h pipe, ID = 1.38 in.

K = 8 (0.0205) = 0.164

(Note: Usually do not select this size. Could go to 1%-

hf = Kvz/2g = (0.5 f 0.164) (1.91)2/2 (32.2) = 0.0853 ft in. Velocity would be even slower.)

fluid

Actual velocity would be: (1Kin. pipe)

Total suction pipe side friction loss:

v = 20 (144)/[(60) (7.48) (1.495)] = 4.29 ft/sec

Ch, = 0.101 + 0.0853 = 0.1863 ft kerosene

This is acceptable. Practical usage range is 3 ft/sec to

9 ft/sec, although lg-in. pipe is not the best size for

Note: when used for pump system balance, this Xhf some plants.

must be used as a negative number (-0.1863) because it is

a pressure loss associated with the fluid flowing. For pipe Reynolds number, R, = 50.6Qp/dp (2-49)

line sizing, the pressure head on the tank of 5 psig and any = 50.6 (20) (0.81 X 62.3)/1.38 (1.125)

elevation difference between tank outlet nozzle and pump = 32,894 (turbulent)

suction centerline do not enter into the calculations. For 1%’’ &/D = 0.0014, Figure 2-11. (2-49A)