Page 103 - Assurance of Sterility for Sensitive Combination Products and Materials

P. 103

Package/container closures 87

• stability testing; accelerated and real-time aging; stable through point of

use; and

• physical protection; performance and dynamics testing; shock, compres-

sion, puncture, and vibration;

o package strength testing; seal strength, material characteristics, and

o package integrity testing; no breach of sterile barrier.

Alternately, the pharmaceutical/biologics industry has seemingly more

requirements for packaging because the number of products, dosage forms,

dosing regimens, packaging components, packaging designs, and materials

is immense (Table 5.2).

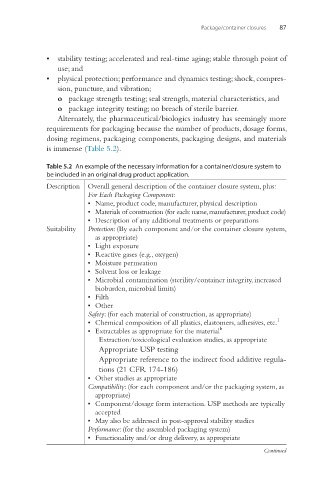

Table 5.2 An example of the necessary information for a container/closure system to

be included in an original drug product application.

Description Overall general description of the container closure system, plus:

For Each Packaging Component:

• Name, product code, manufacturer, physical description

• Materials of construction (for each: name, manufacturer, product code)

• Description of any additional treatments or preparations

Suitability Protection: (By each component and/or the container closure system,

as appropriate)

• Light exposure

• Reactive gases (e.g., oxygen)

• Moisture permeation

• Solvent loss or leakage

• Microbial contamination (sterility/container integrity, increased

bioburden, microbial limits)

• Filth

• Other

Safety: (for each material of construction, as appropriate)

• Chemical composition of all plastics, elastomers, adhesives, etc. 1

• Extractables as appropriate for the material b

Extraction/toxicological evaluation studies, as appropriate

Appropriate USP testing

Appropriate reference to the indirect food additive regula-

tions (21 CFR 174-186)

• Other studies as appropriate

Compatibility: (for each component and/or the packaging system, as

appropriate)

• Component/dosage form interaction. USP methods are typically

accepted

• May also be addressed in post-approval stability studies

Performance: (for the assembled packaging system)

• Functionality and/or drug delivery, as appropriate

Continued