Page 212 - 05. Subyek Teknik Mesin - Automobile Mechanical and Electrical Systems Automotive Technology Vehicle Maintenance and Repair (Vehicle Maintenance Repr Nv2) by Tom Denton

P. 212

2

196 Automobile mechanical and electrical systems

Table 2.1 (Continued)

Stage Description Diagram

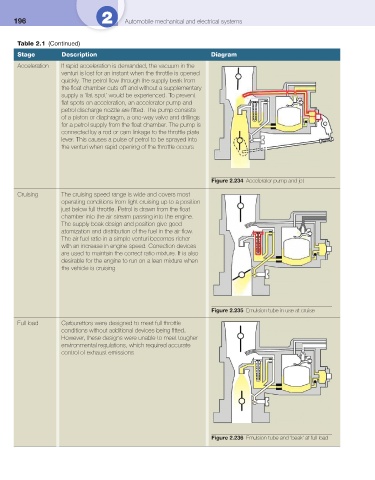

Acceleration If rapid acceleration is demanded, the vacuum in the

venturi is lost for an instant when the throttle is opened

quickly. The petrol fl ow through the supply beak from

the fl oat chamber cuts off and without a supplementary

supply a ‘fl at spot’ would be experienced. To prevent

fl at spots on acceleration, an accelerator pump and

petrol discharge nozzle are fi tted. The pump consists

of a piston or diaphragm, a one-way valve and drillings

for a petrol supply from the fl oat chamber. The pump is

connected by a rod or cam linkage to the throttle plate

lever. This causes a pulse of petrol to be sprayed into

the venturi when rapid opening of the throttle occurs

Figure 2.234 Accelerator pump and jet

Cruising The cruising speed range is wide and covers most

operating conditions from light cruising up to a position

just below full throttle. Petrol is drawn from the fl oat

chamber into the air stream passing into the engine.

The supply beak design and position give good

atomization and distribution of the fuel in the air fl ow.

The air fuel ratio in a simple venturi becomes richer

with an increase in engine speed. Correction devices

are used to maintain the correct ratio mixture. It is also

desirable for the engine to run on a lean mixture when

the vehicle is cruising

Figure 2.235 Emulsion tube in use at cruise

Full load Carburettors were designed to meet full throttle

conditions without additional devices being fi tted.

However, these designs were unable to meet tougher

environmental regulations, which required accurate

control of exhaust emissions

Figure 2.236 Emulsion tube and ‘beak’ at full load