Page 76 - 05. Subyek Teknik Mesin - Automobile Mechanical and Electrical Systems Automotive Technology Vehicle Maintenance and Repair (Vehicle Maintenance Repr Nv2) by Tom Denton

P. 76

1 61

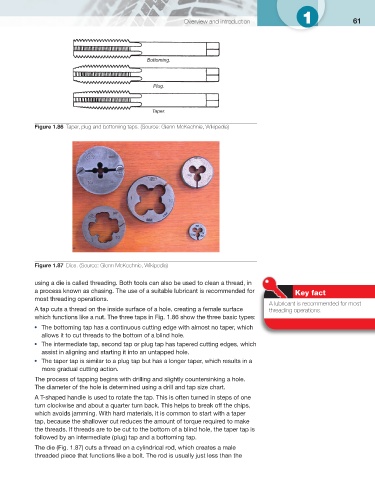

Figure 1.86 Taper, plug and bottoming taps. (Source: Glenn McKechnie, Wikipedia)

Figure 1.87 Dies. (Source: Glenn McKechnie, Wikipedia)

using a die is called threading. Both tools can also be used to clean a thread, in

a process known as chasing. The use of a suitable lubricant is recommended for Key fact

most threading operations.

A lubricant is recommended for most

A tap cuts a thread on the inside surface of a hole, creating a female surface threading operations.

which functions like a nut. The three taps in Fig. 1.86 show the three basic types:

The bottoming tap has a continuous cutting edge with almost no taper, which

●

allows it to cut threads to the bottom of a blind hole.

The intermediate tap, second tap or plug tap has tapered cutting edges, which

●

assist in aligning and starting it into an untapped hole.

The taper tap is similar to a plug tap but has a longer taper, which results in a

●

more gradual cutting action.

The process of tapping begins with drilling and slightly countersinking a hole.

The diameter of the hole is determined using a drill and tap size chart.

A T-shaped handle is used to rotate the tap. This is often turned in steps of one

turn clockwise and about a quarter turn back. This helps to break off the chips,

which avoids jamming. With hard materials, it is common to start with a taper

tap, because the shallower cut reduces the amount of torque required to make

the threads. If threads are to be cut to the bottom of a blind hole, the taper tap is

followed by an intermediate (plug) tap and a bottoming tap.

The die ( Fig. 1.87 ) cuts a thread on a cylindrical rod, which creates a male

threaded piece that functions like a bolt. The rod is usually just less than the