Page 185 - Automotive Engineering Powertrain Chassis System and Vehicle Body

P. 185

Hybrid vehicle design CHAPTER 7.1

as well as improved failure protection under the 100 000 g 7.1.4 Series-production

loading. The motor is of the exterior type with rotor out-

side the stator. High speed operation is possible as the hybrid-drive cars

rotor is merely a steel cylinder with permanent magnets on

its inside. All windings are contained in the stator, having During the early stages of introducing hybrid vehicles

hollow journals at its ends for feeding electrical energy, into the urban scene, state or local authorities may well

cooling and lubrication fluids. Carefully designed supports offer direct and indirect financial inducements to get

for the high speed ball bearings allows the rotor to run these ‘clean vehicles’ into areas that suffer from atmo-

‘overcritical’ without serious vibration modes. Bearings, spheric pollution by motor transport. Now Toyota are

rotor andstatorarevacuum-enclosedforreducingwindage manufacturing their Prius, Fig. 7.1-13, at the rate of 1000

losses and for safety reasons. The containment is cardani- a month and these cars are selling well in Japan. The

cally suspended to avoid gyroscopic effects. Japanese Government, in a deliberate effort to curb

The power converter, (b), controls exchange of elec- urban pollution in Japan, is subsidizing the manufacture

trical power between the 3 phase terminals of the motor/ and sales drive by a variety of tax concessions, including

generator and the DC load. Of the current source in- one that directly benefits the user/operator of the hybrid

verter (CSI) type, it comprises a full bridge with six saloon. The deal with the Japanese Government has

semiconductor switches and GTO thyristors. The latter enabled Toyota to offer these cars as a competitive

are driven by measurements by the CSI of rotor position, package, when taking these taxation inducements into

DC voltage and current. When used as a sole driving account. Toyota have found a technical solution, which,

source the Emafer is charged at bus stops by overhead in engineering terms, is both ingenious and realistic. The

supply contacts. In a hybrid-drive line, an IC engine on company have made use of various new technologies to

board, with generator, supplies the average power reduce the weight of the vehicle and its major compo-

demand, with the Emafer taking care of fluctuations nents and systems. For example, the rolling resistance of

about the average, the flywheel extracting or applying the tyres has also been minimized, which reduces power

power according to braking or accelerating mode. demand by about 5–8%.

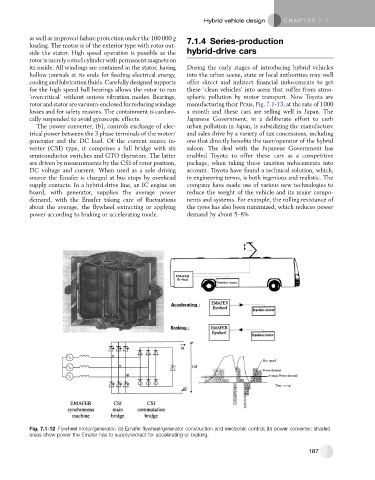

Fig. 7.1-12 Flywheel motor/generator: (a) Emafer flywheel/generator construction and electronic control; (b) power converter: shaded

areas show power the Emafer has to supply/extract for accelerating or braking.

187