Page 250 - Automotive Engineering Powertrain Chassis System and Vehicle Body

P. 250

CH AP TER 8 .1 Types of suspension and drive

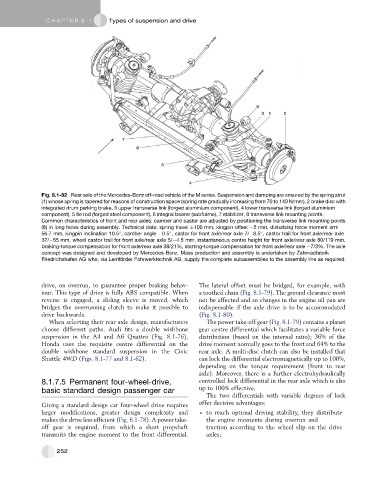

Fig. 8.1-82 Rear axle of the Mercedes-Benz off-road vehicle of the M series. Suspension and damping are ensured by the spring strut

(1) whose spring is tapered for reasons of construction space (spring rate gradually increasing from 70 to 140 N/mm), 2 brake disc with

integrated drum parking brake, 3 upper transverse link (forged aluminium component), 4 lower transverse link (forged aluminium

component), 5 tie rod (forged steel component), 6 integral bearer (subframe), 7 stabilizer, 8 transverse link mounting points.

Common characteristics of front and rear axles: camber and castor are adjusted by positioning the transverse link mounting points

(8) in long holes during assembly. Technical data: spring travel 100 mm, kingpin offset 5 mm, disturbing force moment arm

56.7 mm, kingpin inclination 10.5 , camber angle 0.5 , castor for front axle/rear axle 7/ 8.5 , castor trail for front axle/rear axle

37/ 55 mm, wheel castor trail for front axle/rear axle 5/ 4.5 mm, instantaneous centre height for front axle/rear axle 80/119 mm,

braking-torque compensation for front axle/rear axle 38/21%, starting-torque compensation for front axle/rear axle 7/3%. The axle

concept was designed and developed by Mercedes-Benz. Mass production and assembly is undertaken by Zahnradfabrik

Friedrichshafen AG who, via Lemfo ¨ rder Fahrwerktechnik AG, supply the complete subassemblies to the assembly line as required.

drive, on overrun, to guarantee proper braking behav- The lateral offset must be bridged, for example, with

iour. This type of drive is fully ABS compatible. When a toothed chain (Fig. 8.1-79). The ground clearance must

reverse is engaged, a sliding sleeve is moved, which not be affected and so changes in the engine oil pan are

bridges the overrunning clutch to make it possible to indispensable if the axle drive is to be accommodated

drive backwards. (Fig. 8.1-80).

When selecting their rear axle design, manufacturers The power take-off gear (Fig. 8.1-79) contains a planet

choose different paths. Audi fits a double wishbone gear centre differential which facilitates a variable force

suspension in the A4 and A6 Quattro (Fig. 8.1-76), distribution (based on the internal ratio); 36% of the

Honda uses the requisite centre differential on the drive moment normally goes to the front and 64% to the

double wishbone standard suspension in the Civic rear axle. A multi-disc clutch can also be installed that

Shuttle 4WD (Figs. 8.1-77 and 8.1-62). can lock the differential electromagnetically up to 100%,

depending on the torque requirement (front to rear

axle). Moreover, there is a further electrohydraulically

8.1.7.5 Permanent four-wheel-drive, controlled lock differential in the rear axle which is also

basic standard design passenger car up to 100% effective.

The two differentials with variable degrees of lock

Giving a standard design car four-wheel drive requires offer decisive advantages:

larger modifications, greater design complexity and to reach optimal driving stability, they distribute

makes the drive less efficient (Fig. 8.1-78). A power take- the engine moments during overrun and

off gear is required, from which a short propshaft traction according to the wheel slip on the drive

transmits the engine moment to the front differential. axles;

252