Page 80 - Automotive Engineering Powertrain Chassis System and Vehicle Body

P. 80

CH AP TER 4 .1 Digital engine control systems

This chapter explains how the microcontroller under associated ROM contains the program for each mode as

program control is responsible for generating the elec- well as calibration parameters and lookup tables. The

trical signals that operate the fuel injectors and trigger earliest such systems incorporated 8-bit microproces-

the ignition pulses. This chapter also discusses secondary sors, although the trend is toward implementation with

functions (including management of secondary air that 32-bit microprocessors. The microcontroller under pro-

must be provided to the catalytic converter exhaust gas gram control generates output electrical signals to

recirculation (EGR) regulation and evaporative emission operate the fuel injectors so as to maintain the desired

control). mixture and ignition to optimize performance. The cor-

rect mixture is obtained by regulating the quantity of fuel

delivered into each cylinder during the intake stroke in

4.1.3 Digital engine control features accordance with the air mass.

In determining the correct fuel flow, the controller

The primary purpose of the electronic engine control obtains a measurement or estimate of the mass air flow

system is to regulate the mixture (i.e., air–fuel), the ig- (MAF) rate into the cylinder. The measurement is

nition timing, and EGR. Virtually all major manufac- obtained using an MAF sensor. Alternatively, the MAF

turers of cars sold in the United States (both foreign and rate is estimated (calculated) using the speed–density

domestic) use the three-way catalyst for meeting exhaust method. This estimate can be found from measurement

emission constraints. For such cars, the air/fuel ratio is of the intake manifold absolute pressure (MAP), the

held as closely as possible to the stoichiometric value of revolutions per minute (RPM) and the inlet air

about 14.7 for as much of the time as possible. Ignition temperature.

timing and EGR are controlled separately to optimize Using this measurement or estimate, the quantity of

performance and fuel economy. fuel to be delivered is determined by the controller in

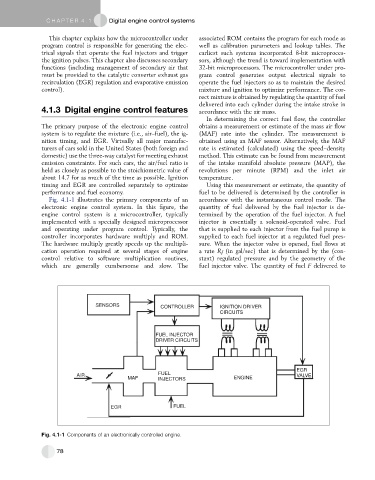

Fig. 4.1-1 illustrates the primary components of an accordance with the instantaneous control mode. The

electronic engine control system. In this figure, the quantity of fuel delivered by the fuel injector is de-

engine control system is a microcontroller, typically termined by the operation of the fuel injector. A fuel

implemented with a specially designed microprocessor injector is essentially a solenoid-operated valve. Fuel

and operating under program control. Typically, the that is supplied to each injector from the fuel pump is

controller incorporates hardware multiply and ROM. supplied to each fuel injector at a regulated fuel pres-

The hardware multiply greatly speeds up the multipli- sure. When the injector valve is opened, fuel flows at

cation operation required at several stages of engine a rate R f (in gal/sec) that is determined by the (con-

control relative to software multiplication routines, stant) regulated pressure and by the geometry of the

which are generally cumbersome and slow. The fuel injector valve. The quantity of fuel F delivered to

SENSORS CONTROLLER IGNITION DRIVER

CIRCUITS

FUEL INJECTOR

DRIVER CIRCUITS

EGR

AIR FUEL VALVE

MAF INJECTORS ENGINE

EGR FUEL

Fig. 4.1-1 Components of an electronically controlled engine.

78