Page 300 - Battery Reference Book

P. 300

Zinc-air primary batteries 26/3

Zinc-air primary batteries source. Cells have been designed with a structure

that contains two cathodes (air electrodes) in parallel

The chemical reactions occuning in a zinc-air cell are and one anode (Figure 26.l(a)). The two cathodes are

as follows: cemented to a frame to form the cell container. With air

Cathode 02 + :2Hz0 + 4e- = 40H- (26.1) cells, it is not necessary to incorporate a depolarizer,

such as manganese dioxide, into the cell. Instead, oxy-

Anode Zn + 40H- + Zn (OH):- (26.2) gen from the air is used as the depolarizer. The replace-

able element in the cell consists of a highly porous

Net reaction Zn + 02 + 2H20 + 2e- = Zn (OH);- (26.3) zinc anode, containing the proper amount of potassium

The theoretical voltage of this cell is 1.64V. Most hydroxide in dry form and wrapped with appropriate

practical cells have an open circuit voltage range separator materials. When a cell is ready to be activ-

between 1.42 and 1.52V, the lower values being ated, the cell container is filled with water. The zinc

atributed to peroxide build-up at the electrode surface. anode with the dry potassium hydroxide and separator

Although zinc-air batteries have been in use for is then inserted into the cell. The cell is now ready for

many years, their use has been restricted to very low- use. Multi-cell batteries can be constructed. Spacers

rate applications. As a result of the work performed on are placed between cells to permit air flow by convec-

fuel cells and advancements in technology for making tion. For heavy loads and large batteries, convection

thin gas electrodes that operate at high current dens- may not suffice and blowers are required. When spent,

ities. zinc-sir cells are now being examined as a power the zinc anodes are replaced with new ones for another

Cell top

with

anode

ib

affixed

Electroll e

seal

Perforated

intercell

separator Open cell

frame

\Porous

cathode Zinc

containing negative

Pt catalyst

Porous anode

ZnfKOH .-

with separator Top cover (A)

paper KOH

electrolyte Seal (E)

Metal can (G)

Electrolyte Separator and

seal

electrolyte (C)

Catalyst and

metal grid (C)

air access PTFE (F)

(a1 (b)

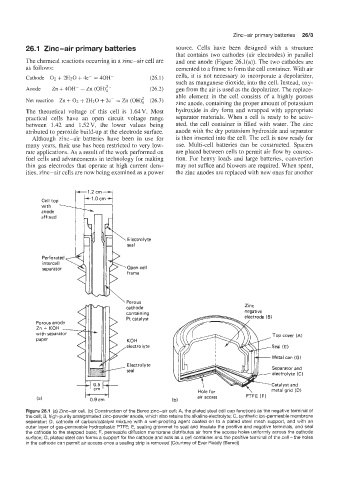

Figure 26.1 (a) Zinc-air cell. (b) Construction of the Berec zinc-air cell: A, the plated steel cell cap functions as the negative terminai of

the cell; B, high-purity amalgamated zinc-powder anode, which also retains the alkaline electrolyte; C, synthetic ion-permeable membrane

separator; D, cathode of carbonkatalyst mixture with a wet-proofing agent coated on to a plated steel mesh support, and with an

outer layer of gas-permeable hydroplastic PTFE; E, sealing grommet to seal and insulate the positive and negative terminals, and seal

the cathode to the stepped base; F, permeable diffusion membrane distributes air from the access holes uniformly across the cathode

surface; G, plated steel can forms a support for the cathode and acts as a cell container and the positive terminal of the cell -the holes

in the cathode cai permit air access once a sealing strip is removed (Courtesy of Ever Ready (Berec))