Page 122 - Biaxial Multiaxial Fatigue and Fracture

P. 122

Long-Lije Multiaxial Fatigue of a Nodular Gmphite Cast Iron 107

the material. Findley identified a critical plane for fatigue crack initiation and growth that is

dependent on both alternating shear stress and maximum normal stress. The combined action

of shear and normal stresses is responsible for fatigue damage and the maximum value of the

quantity in parentheses is used rather than the maximum value of shear stress.

Other successful long-life shear stress based models for multiaxial fatigue have the same

general form as Eq. (1) and include both a shear stress and a normal stress terms to account for

observed mean stress and combined loading effects. Several examples long-life shear stress

based models and the shear and normal stress terms employed in these models are listed in

Table 1. Of these examples, all except the Sines model fall into the critical plane category

because Tresca shear stress is associated with a specific plane.

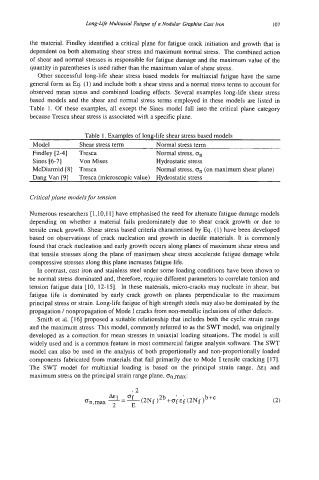

Table 1. Examples of long-life shear stress based models

Model Shear stress term Normal stress term

Findley [2-41 Tresca Normal stress, On

Sines [6-71 Von Mises Hydrostatic stress

McDiarmid [8] Tresca Normal stress, On (on maximum shear plane)

Dang Van [9] Tresca (microscopic value) Hydrostatic stress

Critical plane models for tension

Numerous researchers [ 1,10,11] have emphasised the need for alternate fatigue damage models

depending on whether a material fails predominately due to shear crack growth or due to

tensile crack growth. Shear stress based criteria characterised by Eq. (1) have been developed

based on observations of crack nucleation and growth in ductile materials. It is commonly

found that crack nucleation and early growth occurs along planes of maximum shear stress and

that tensile stresses along the plane of maximum shear stress accelerate fatigue damage while

compressive stresses along this plane increases fatigue life.

In contrast, cast iron and stainless steel under some loading conditions have been shown to

be normal stress dominated and, therefore, require different parameters to correlate torsion and

tension fatigue data [IO, 12-15]. In these materials, micro-cracks may nucleate in shear, but

fatigue life is dominated by early crack growth on planes perpendicular to the maximum

principal stress or strain. Long-life fatigue of high strength steels may also be dominated by the

propagation / nonpropagation of Mode I cracks from non-metallic inclusions of other defects.

Smith et al. [ 161 proposed a suitable relationship that includes both the cyclic strain range

and the maximum stress. This model, commonly referred to as the SWT model, was originally

developed as a correction for mean stresses in uniaxial loading situations. The model is still

widely used and is a common feature in most commercial fatigue analysis software. The SWT

model can also be used in the analysis of both proportionally and non-proportionally loaded

components fabricated from materials that fail primarily due to Mode I tensile cracking [ 171.

The SWT model for multiaxial loading is based on the principal strain range, AEI and

maximum stress on the principal strain range plane, On,max:

On,max -=- *" Of (2Nf)2b+~;~;(2Nf)b+c

2 E