Page 128 - Biaxial Multiaxial Fatigue and Fracture

P. 128

Long-Life Multiaxial Fatigue of a Nodular Gmphite Cast Iron 113

Specimens

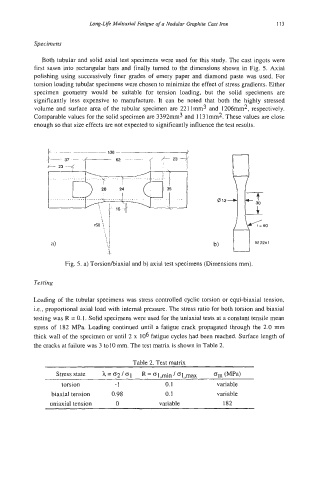

Both tubular and solid axial test specimens were used for this study. The cast ingots were

first sawn into rectangular bars and finally turned to the dimensions shown in Fig. 5. Axial

polishing using successively finer grades of emery paper and diamond paste was used. For

torsion loading tubular specimens were chosen to minimize the effect of stress gradients. Either

specimen geometry would be suitable for tension loading, but the solid specimens are

significantly less expensive to manufacture. It can be noted that both the highly stressed

volume and surface area of the tubular specimen are 221 lmm3 and 1206mm2, respectively.

Comparable values for the solid specimen are 3392mm3 and 1131mm2. These values are close

enough so that size effects are not expected to significantly influence the test results.

Fig. 5. a) Torsionhiaxial and b) axial test specimens (Dimensions mm).

Testing

hading of the tubular specimens was stress controlled cyclic torsion or equi-biaxial tension,

i.e., proportional axial load with internal pressure. The stress ratio for both torsion and biaxial

testing was R = 0.1. Solid specimens were used for the uniaxial tests at a constant tensile mean

stress of 182 MPa. Loading continued until a fatigue crack propagated through the 2.0 mm

thick wall of the specimen or until 2 x lo6 fatigue cycles had been reached. Surface length of

the cracks at failure was 3 to10 mm. The test matrix is shown in Table 2.

Table 2. Test matrix

Stress state h = 02 / 01 R = 01 ,min I 01 ,max Om (MPa)

torsion -1 0.1 variable

biaxial tension 0.98 0.1 variable

uniaxial tension 0 variable I82