Page 142 - Biaxial Multiaxial Fatigue and Fracture

P. 142

The InJuence of Static Mean Stresses Applied Normal to the Maximum Shear Planes in ._. 127

‘Amplitude

‘Amplitude R, =-1

R =-I

1 t!

.*, +

int * Mean

4 I

int cr Mean

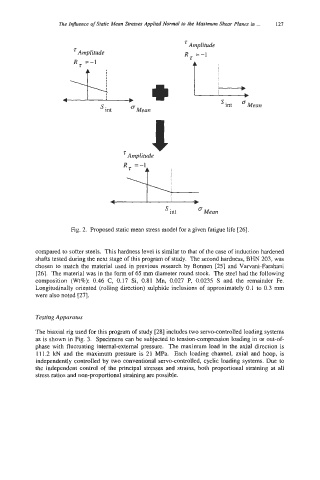

Fig. 2. Proposed static mean stress model for a given fatigue life [26].

compared to softer steels. This hardness level is similar to that of the case of induction hardened

shafts tested during the next stage of this program of study. The second hardness, BHN 203, was

chosen to match the material used in previous research by Bonnen [25] and Varvani-Farahani

[26]. The material was in the form of 65 rnm diameter round stock. The steel had the following

composition (Wt%): 0.46 C, 0.17 Si, 0.81 Mn, 0.027 P, 0.0235 S and the remainder Fe.

Longitudinally oriented (rolling direction) sulphide inclusions of approximately 0.1 to 0.3 mm

were also noted [27].

Testing Apparatus

The biaxial rig used for this program of study [28] includes two servo-controlled loading systems

as is shown in Fig. 3. Specimens can be subjected to tension-compression loading in or out-of-

phase with fluctuating internal-external pressure. The maximum load in the axial direction is

11 1.2 kN and the maximum pressure is 21 MPa. Each loading channel, axial and hoop, is

independently controlled by two conventional servo-controlled, cyclic loading systems. Due to

the independent control of the principal stresses and strains, both proportional straining at all

stress ratios and non-proportional straining are possible.