Page 20 - Biaxial Multiaxial Fatigue and Fracture

P. 20

Assessment of Welded Structures by a Structural Multiaxial Fatigue Approach 5

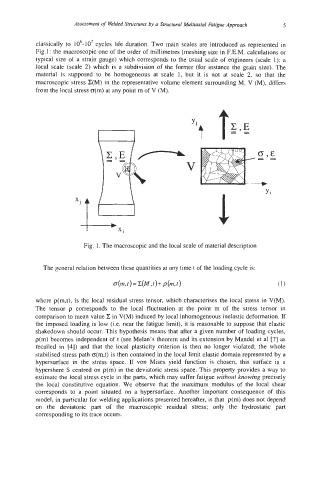

classically to 106-107 cycles life duration. Two main scales are introduced as represented in

Fig. 1 : the macroscopic one of the order of millimetres (meshing size in F.E.M. calculations or

typical size of a strain gauge) which corresponds to the usual scale of engineers (scale 1); a

local scale (scale 2) which is a subdivision of the former (for instance the grain size). The

material is supposed to be homogeneous at scale 1, but it is not at scale 2, so that the

macroscopic stress Z(M) in the representative volume element surrounding M, V (M), differs

from the local stress a(m) at any point m of V (M).

Fig. 1. The macroscopic and the local scale of material description

The general relation between these quantities at any time t of the loading cycle is:

where p(m,t), is the local residual stress tensor, which characterises the local stress in V(M).

The tensor p corresponds to the local fluctuation at the point m of the stress tensor in

comparison to mean value in V(M) induced by local inhomogeneous inelastic deformation. If

the imposed loading is low (i.e. near the fatigue limit), it is reasonable to suppose that elastic

shakedown should occur. This hypothesis means that after a given number of loading cycles,

p(m) becomes independent oft (see Melan's theorem and its extension by Mandel et al [7] as

recalled in [4]) and that the local plasticity criterion is then no longer violated; the whole

stabilised stress path a(m,t) is then contained in the local limit elastic domain represented by a

hypersurface in the stress space. If von Mises yield function is chosen, this surface is a

hypershere S centred on p(m) in the deviatoric stress space. This property provides a way to

estimate the local stress cycle in the parts, which may suffer fatigue without knowing precisely

the local constitutive equation. We observe that the maximum modulus of the local shear

corresponds to a point situated on a hypersurface. Another important consequence of this

model, in particular for welding applications presented hereafter, is that p(m) does not depend

on the deviatoric part of the macroscopic residual stress; only the hydrostatic part

corresponding to its trace occurs.