Page 25 - Biaxial Multiaxial Fatigue and Fracture

P. 25

10 K, DANG VAN, A. BIGNONNET AND 1L. FAYARD

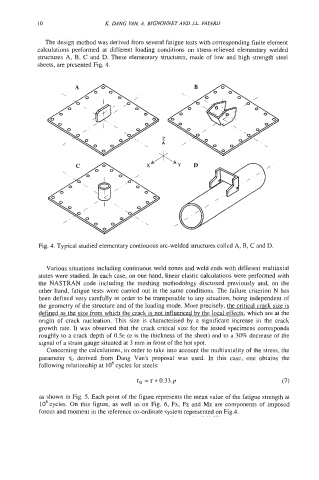

The design method was derived from several fatigue tests with corresponding finite element

calculations performed at different loading conditions on stress-relieved elementary welded

structures A, B, C and D. These elementary structures, made of low and high strength steel

sheets, are presented Fig. 4.

/

Fig. 4. Typical studied elementary continuous arc-welded structures called A, B, C and D.

Various situations including continuous weld zones and weld ends with different multiaxial

states were studied. In each case, on one hand, linear elastic calculations were performed with

the NASTRAN code including the meshing methodology discussed previously and, on the

other hand, fatigue tests were carried out in the same conditions. The failure criterion N has

been defined very carefully in order to be transposable to any situation, being independent of

the geometry of the structure and of the loading mode. More precisely, the critical crack size is

defined as the size from which the crack is not influenced bv the local effects, which are at the

origin of crack nucleation. This size is characterised by a significant increase in the crack

growth rate. It was observed that the crack critical size for the tested specimens corresponds

roughly to a crack depth of 0.5e (e is the thickness of the sheet) and to a 30% decrease of the

signal of a strain gauge situated at 3 mm in front of the hot spot.

Concerning the calculations, in order to take into account the multiaxiality of the stress, the

parameter TO derived from Dang Van's proposal was used. In this case, one obtains the

following relationship at lo6 cycles for steels:

as shown in Fig. 5. Each point of the figure represents the mean value of the fatigue strength at

lo6 cycles. On this figure, as well as on Fig. 6, Fx, Fz and Mz are components of imposed

forces and moment in the reference co-ordinate system represented on Fig.4.