Page 292 - Biaxial Multiaxial Fatigue and Fracture

P. 292

276 A. BUCZYNSKI AND G. GLINKA

stress increment. The slope of the current linear segment of the stress-strain curve defines the

plastic modulus, AcreqlA€e:, necessary for the determination of the parameter, dh, in the

constitutive equation (IO). The plasticity models are described in most publications, as

algorithms for calculating strain increments that result from given series of stress increments or

vice versa. This is called as the stress or strain controlled input. In the case of the notch analysis

neither stresses nor strains are directly inputted into the plasticity model. The input is given in

the form of the total deviatoric strain energy density increments and both the deviatoric strain

and stress increments are to be found simultaneously by solving the equation set (12). Therefore,

the plasticity model is needed only to indicate which work-hardening surface is to be active

during current load increment, which subsequently determines the instantaneous value of the

parameter dh. In order to find the actual elastic-plastic deviatoric stress and strain increment ASit

and Aega from the equation set (12), the value of parameter dh is determined first according to

the current configuration of plasticity surfaces. After calculating all stress increments, Asit, and

subsequently, AGi?, the plasticity surfaces are translated as shown in Fig. 6. The process is

repeated for each subsequent increment of the “elastic” input, Ac;.

The Mroz [9] and Garud [ 101 models were chosen here as an illustration. Obviously, any other

plasticity model can be associated with the incremental stress-strain notch analysis proposed

above. The Garud plasticity model was employed in the analysis discussed below.

COMPARiSON OF CALCULATED ELASTIC-PLASTIC NOTCH TIP STRAINS AND

STRESSES WITH ELASTIC-PLASTIC FINITE ELEMENT DATA

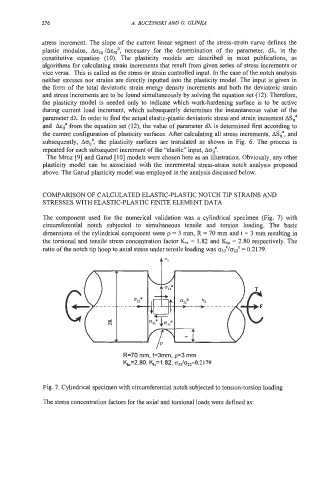

The component used for the numerical validation was a cylindrical specimen (Fig. 7) with

circumferential notch subjected to simultaneous tensile and torsion loading. The basic

dimensions of the cylindrical component were p = 3 mm, R = 70 mm and t = 3 mm resulting in

the torsional and tensile stress concentration factor K,, = 1.82 and Kt, = 2.80 respectively. The

ratio of the notch tip hoop to axial stress under tensile loading was ~33%22~ = 0.2179.

f x3

R=70 rnrn, t=3mrn. p=3 rnrn

b0=2.80, bT=1 .82, a,,/0,~=0.2179

Fig. 7. Cylindrical specimen with circumferential notch subjected to tension-torsion loading

The stress concentration factors for the axial and torsional loads were defined as: