Page 407 - Biaxial Multiaxial Fatigue and Fracture

P. 407

A Multiaxial Fatigue Life Criterion for Non-Symmetrical and Non-Proportional Elasto-Plastic ... 39 1

where a,p,A,p are four material parameters that must be identified for each material by

fitting experimental results.

In most cases this approach, though seeming sound from a mathematical point of view, is

impractical and adds little to the description of the real material behaviour. Actually, the

identification of the four material constants requires additional test campaigns, which not only

increase the costs but also introduce severe mathematical complexities in building a model for

fatigue life prediction.

Instead, a few considerations regarding the form of Eq. (1 7) will reduce this formula to what

is believed to be the essential needs of fatigue analyses. In Eq. (1 7) the effect of the alternating

strain is considered twice, by the quadratic term ( ya,O f and by the linear term A yeff Both

terms being positive it is believed that retaining only one of them would be sufficient to

capture the effect of yefF,O. The quadratic term is retained here. If experiments under strain

control with and without mean strain are compared (e.g. axial low-cycle fatigue experiments

on cylindrical smooth specimens with strain ratios &=O and &=-l, respectively), it may be

observed that for higher strain ranges the mean strain has less influence on the fatigue life than

for smaller strain ranges. This behaviour may be partially explained by the fact that for higher

strain ranges mean stress relaxation is usually observed, so that mean stresses disappear after

the first few cycles, while for smaller applied strain these stresses are kept constant during the

life of a component and they do affect its durability. In the light of this, it seems a reasonable

choice to neglect the quadratic term fl(yeETmy in Eq. (17). Further inspecting the effect of

y&m, it is noticed that two possibilities are now left. First, one may hold both the interaction

term (c~y&.~)y&,~ and the linear term pyeff,,,, at the cost of two additional material

parameters, a, p . Second, one can retain the interaction term only, introducing thus only one

additional parameter with respect to the fully reversed loading case. This last choice is

followed in the present work.

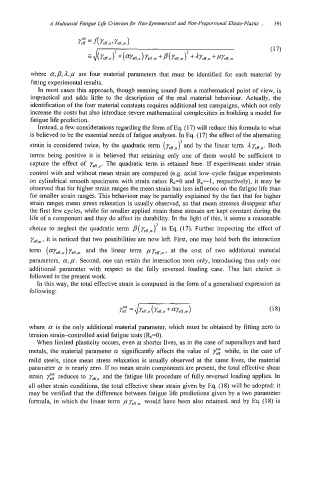

In this way, the total effective strain is computed in the form of a generalised expression as

following:

where a is the only additional material parameter, which must be obtained by fitting zero to

tension strain-controlled axial fatigue tests (&=O).

When limited plasticity occurs, even at shorter lives, as in the case of superalloys and hard

metals, the material parameter a significantly affects the value of while, in the case of

mild steels, since mean stress relaxation is usually observed at the same lives, the material

parameter a is nearly zero. If no mean strain components are present, the total effective shear

strain yz reduces to yefFp and the fatigue life procedure of llly reversed loading applies. In

all other strain conditions, the total effective shear strain given by Eq. (18) will be adopted: it

may be verified that the difference between fatigue life predictions given by a two parameter

formula, in which the linear term p yeff,m would have been also retained, and by Eq. (18) is