Page 482 - Biaxial Multiaxial Fatigue and Fracture

P. 482

.

466 1L.T. SAWS ET AL.

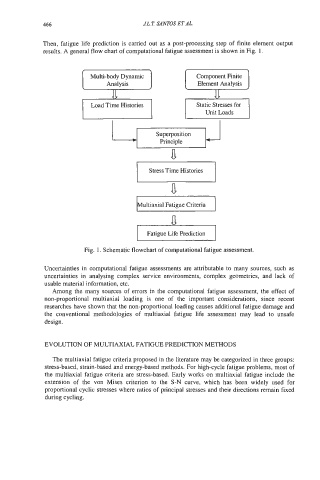

Then, fatigue life prediction is carried out as a post-processing step of finite element output

results. A general flow chart of computational fatigue assessment is shown in Fig. 1.

Analysis Element Analysis

I

Static Stresses for

Load Time Histories

Loads

Unit

Principle

a l

I Stress Time Histories I

a

ultiaxial Fatigue Criteria

Fatigue Life Prediction

Fig. 1. Schematic flowchart of computational fatigue assessment.

Uncertainties in computational fatigue assessments are attributable to many sources, such as

uncertainties in analysing complex service environments, complex geometries, and lack of

usable material information, etc.

Among the many sources of errors in the computational fatigue assessment, the effect of

non-proportional multiaxial loading is one of the important considerations, since recent

researches have shown that the non-proportional loading causes additional fatigue damage and

the conventional methodologies of multiaxial fatigue life assessment may lead to unsafe

design.

EVOLUTION OF MULTIAXIAL FATIGUE PREDICTION METHODS

The multiaxial fatigue criteria proposed in the literature may be categorized in three groups:

stress-based, strain-based and energy-based methods. For high-cycle fatigue problems, most of

the multiaxial fatigue criteria are stress-based. Early works on multiaxial fatigue include the

extension of the von Mises criterion to the S-N curve, which has been widely used for

proportional cyclic stresses where ratios of principal stresses and their directions remain fixed

during cycling.