Page 221 - Biofuels Refining and Performance

P. 221

204 Chapter Seven

7.7 Alcohols in CI Engine

Although the physical and thermodynamic characteristics of alcohols do

not make them particularly suitable for compression ignition (CI)

engines, with certain modifications, however, they can also be used in

CI engines. In heavy vehicles powered by CI engines, ethanol carbure-

tion can be employed for bi-fuel operation of the engine with proportional

savings in diesel oil. The various methods for using alcohols with diesel

are fumigation, dual injection, and alcohol–diesel emulsions.

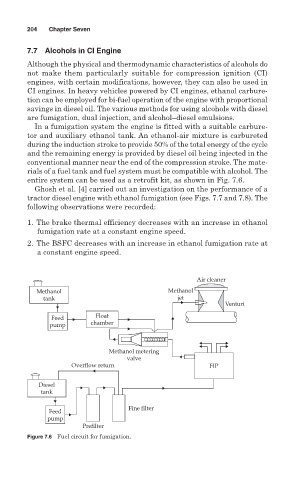

In a fumigation system the engine is fitted with a suitable carbure-

tor and auxiliary ethanol tank. An ethanol-air mixture is carbureted

during the induction stroke to provide 50% of the total energy of the cycle

and the remaining energy is provided by diesel oil being injected in the

conventional manner near the end of the compression stroke. The mate-

rials of a fuel tank and fuel system must be compatible with alcohol. The

entire system can be used as a retrofit kit, as shown in Fig. 7.6.

Ghosh et al. [4] carried out an investigation on the performance of a

tractor diesel engine with ethanol fumigation (see Figs. 7.7 and 7.8). The

following observations were recorded:

1. The brake thermal efficiency decreases with an increase in ethanol

fumigation rate at a constant engine speed.

2. The BSFC decreases with an increase in ethanol fumigation rate at

a constant engine speed.

Air cleaner

Methanol Methanol

tank jet

Venturi

Float

Feed

pump chamber

Methanol metering

valve

Overflow return FIP

Diesel

tank

Fine filter

Feed

pump

Prefilter

Figure 7.6 Fuel circuit for fumigation.