Page 226 - Biofuels Refining and Performance

P. 226

Ethanol and Methanol as Fuels in Internal Combustion Engines 209

IC engine fuels. Availability from indigenous sources, ease of handling,

low emission, and high thermal efficiency obtainable with its use make

methanol a logical alternative fuel for vehicular engines.

7.8.1 Production of methanol

Methanol can be produced from resources such as coal, natural gas, oil

shell, and farm waste, which are abundant worldwide. But methanol

from natural gas is unlikely to provide a large greenhouse benefit, not

more than a 10% reduction in emissions with quite optimistic assump-

tions. It is not considered as a main raw material to produce methanol.

For countries having vast reserves of coal but small oil deposits,

methanol from coal can provide an indigenous substitute to oil. But this

method has an adverse effect on greenhouse gases and is very expen-

sive, requiring capital investments that can increase the price by 50%.

In India, there is an abundant production of sugarcane. The govern-

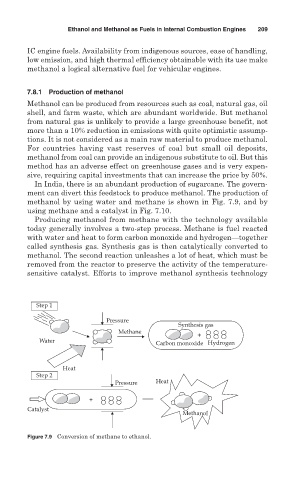

ment can divert this feedstock to produce methanol. The production of

methanol by using water and methane is shown in Fig. 7.9, and by

using methane and a catalyst in Fig. 7.10.

Producing methanol from methane with the technology available

today generally involves a two-step process. Methane is fuel reacted

with water and heat to form carbon monoxide and hydrogen—together

called synthesis gas. Synthesis gas is then catalytically converted to

methanol. The second reaction unleashes a lot of heat, which must be

removed from the reactor to preserve the activity of the temperature-

sensitive catalyst. Efforts to improve methanol synthesis technology

Step 1

Pressure

Synthesis gas

Methane

+

Water Carbon monoxide Hydrogen

Heat

Step 2

Pressure Heat

+

Catalyst

Methanol

Figure 7.9 Conversion of methane to ethanol.