Page 229 - Biofuels Refining and Performance

P. 229

212 Chapter Seven

Carburetor

EGR valve

Engine coolant

heat exchanger

Air pump

Intake

manifold

Exhaust

manifold

Stock motor Exhaust purifier

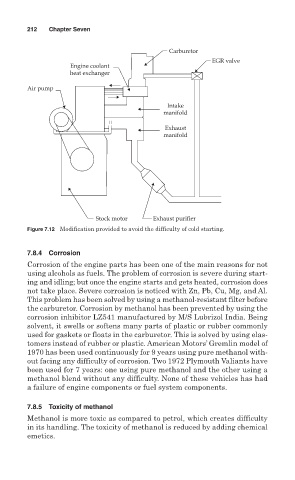

Figure 7.12 Modification provided to avoid the difficulty of cold starting.

7.8.4 Corrosion

Corrosion of the engine parts has been one of the main reasons for not

using alcohols as fuels. The problem of corrosion is severe during start-

ing and idling; but once the engine starts and gets heated, corrosion does

not take place. Severe corrosion is noticed with Zn, Pb, Cu, Mg, and Al.

This problem has been solved by using a methanol-resistant filter before

the carburetor. Corrosion by methanol has been prevented by using the

corrosion inhibitor LZ541 manufactured by M/S Lubrizol India. Being

solvent, it swells or softens many parts of plastic or rubber commonly

used for gaskets or floats in the carburetor. This is solved by using elas-

tomers instead of rubber or plastic. American Motors’ Gremlin model of

1970 has been used continuously for 9 years using pure methanol with-

out facing any difficulty of corrosion. Two 1972 Plymouth Valiants have

been used for 7 years: one using pure methanol and the other using a

methanol blend without any difficulty. None of these vehicles has had

a failure of engine components or fuel system components.

7.8.5 Toxicity of methanol

Methanol is more toxic as compared to petrol, which creates difficulty

in its handling. The toxicity of methanol is reduced by adding chemical

emetics.