Page 246 - Biofuels for a More Sustainable Future

P. 246

A life cycle assessment of tri-generation from biomass waste 221

where Q is the useful thermal/refrigeration energy, T 0 is the dead state

temperature equal to 25°C, and T 1 is the temperature of the thermal fluid

(50°C for heating and 5°C for cooling).

Considering the efficiency of the system components (cogeneration

plant and absorption chiller), the yearly exergy production is

– 1369.9GJ for electricity

– 79.6GJ for heating

– 73.9GJ for cooling

Thus the total exergy production during the whole life cycle of the plant

(30years) is equal to 45,701.9GJ.

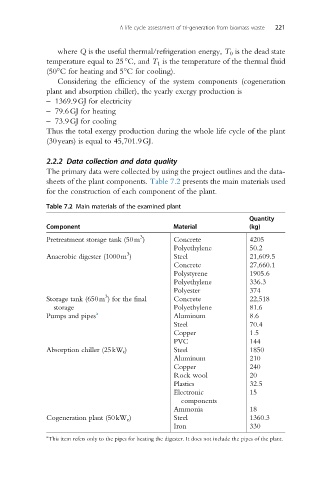

2.2.2 Data collection and data quality

The primary data were collected by using the project outlines and the data-

sheets of the plant components. Table 7.2 presents the main materials used

for the construction of each component of the plant.

Table 7.2 Main materials of the examined plant

Quantity

Component Material (kg)

3

Pretreatment storage tank (50m ) Concrete 4205

Polyethylene 50.2

3

Anaerobic digester (1000m ) Steel 21,609.5

Concrete 27,660.1

Polystyrene 1905.6

Polyethylene 336.3

Polyester 374

3

Storage tank (650m ) for the final Concrete 22,518

storage Polyethylene 81.6

Pumps and pipes a Aluminum 8.6

Steel 70.4

Copper 1.5

PVC 144

Absorption chiller (25kW t ) Steel 1850

Aluminum 210

Copper 240

Rock wool 20

Plastics 32.5

Electronic 15

components

Ammonia 18

Cogeneration plant (50kW e ) Steel 1360.3

Iron 330

a

This item refers only to the pipes for heating the digester. It does not include the pipes of the plant.