Page 247 - Biofuels for a More Sustainable Future

P. 247

222 Biofuels for a More Sustainable Future

The eco-profiles of the raw materials, materials and energy sources, the

transport and end-of-life processes are referred to environmental databases

(Frischknecht et al., 2007).

2.3 Life cycle impact assessment and interpretation

The energy impact (CED) for the functional unit (1MJ of exergy) is

4.91E 02MJ,ofwhichabout96%isnonrenewableenergy(4.71E 02MJ).

The production step is responsible of about 76% of CED (3.73E 02-

MJ), while the operation and end of life give a contribution to the total

impact of about 20% (9.82E 03MJ) and 4% (1.94E 03MJ), respectively.

Focusing on the production step, the steel used in the manufacturing of

the digester is responsible for about 51% of the energy impact, while about

28% of the impact is attributable to the use of steel in the cogeneration plant.

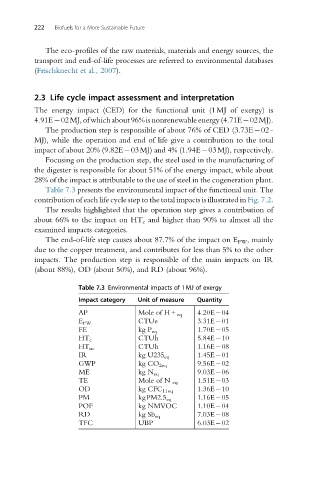

Table 7.3 presents the environmental impact of the functional unit. The

contribution of each life cycle step to the total impacts is illustrated in Fig. 7.2.

The results highlighted that the operation step gives a contribution of

about 66% to the impact on HT c and higher than 90% to almost all the

examined impacts categories.

The end-of-life step causes about 87.7% of the impact on E FW , mainly

due to the copper treatment, and contributes for less than 5% to the other

impacts. The production step is responsible of the main impacts on IR

(about 88%), OD (about 50%), and RD (about 96%).

Table 7.3 Environmental impacts of 1MJ of exergy

Impact category Unit of measure Quantity

AP Mole of H+ eq 4.20E 04

CTUe 3.31E 01

E FW

FE kg P eq 1.70E 05

CTUh 5.84E 10

HT c

CTUh 1.16E 08

HT nc

IR kg U235 eq 1.45E 01

GWP kg CO 2eq 9.56E 02

ME kg N eq 9.03E 06

TE Mole of N eq 1.51E 03

OD kg CFC 11eq 1.36E 10

PM kgPM2.5 eq 1.16E 05

POF kg NMVOC 1.10E 04

RD kg Sb eq 7.03E 08

TFC UBP 6.03E 02