Page 91 - Biofuels for a More Sustainable Future

P. 91

82 Biofuels for a More Sustainable Future

Paraffins Olefines

diesel gasoline

MTBE

Fischer-Tropsch Acetic acid

Mixture of

alcohols Formaldehyde Ag

Fe CH 3 OH + CO

Cu Co, Rh, Ni

Ru

Ag

ThO 2

Syngas Methanol Olefines

or Cu/ZnO Zeolites

i-C 4 CH 3 OH gasoline

CO + H 2

ZrO 2

H 2 O Co

WGS H 2 O Rh Al 2 MTO

WGS O 3 MTG

Ethanol

H 2 M100

Aldehydes DME M85

N 2 on Fe, FeO DMFC

NH 3 alcohols

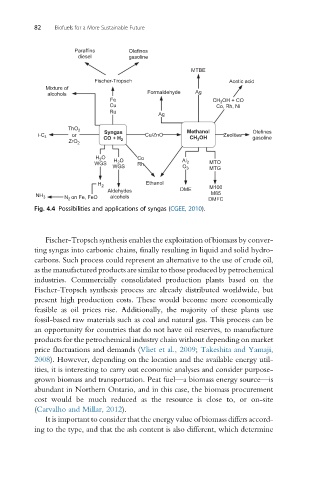

Fig. 4.4 Possibilities and applications of syngas (CGEE, 2010).

Fischer-Tropsch synthesis enables the exploitation of biomass by conver-

ting syngas into carbonic chains, finally resulting in liquid and solid hydro-

carbons. Such process could represent an alternative to the use of crude oil,

as the manufactured products are similar to those produced by petrochemical

industries. Commercially consolidated production plants based on the

Fischer-Tropsch synthesis process are already distributed worldwide, but

present high production costs. These would become more economically

feasible as oil prices rise. Additionally, the majority of these plants use

fossil-based raw materials such as coal and natural gas. This process can be

an opportunity for countries that do not have oil reserves, to manufacture

products for the petrochemical industry chain without depending on market

price fluctuations and demands (Vliet et al., 2009; Takeshita and Yamaji,

2008). However, depending on the location and the available energy util-

ities, it is interesting to carry out economic analyses and consider purpose-

grown biomass and transportation. Peat fuel—a biomass energy source—is

abundant in Northern Ontario, and in this case, the biomass procurement

cost would be much reduced as the resource is close to, or on-site

(Carvalho and Millar, 2012).

It is important to consider that the energy value of biomass differs accord-

ing to the type, and that the ash content is also different, which determine