Page 116 - Biomass Gasification, Pyrolysis And Torrefaction Practical Design and Theory

P. 116

94 Biomass Gasification, Pyrolysis and Torrefaction

the air blast (FAO, 1985, p. 8). A major motivation of using biocoke in blast

furnace is to replace coal and thereby reduce net CO 2 emission from the iron

and steel industries. Pulverized biocoke may be injected directly into blast

furnace. Alternately, torrefied biomass or charcoal could be mixed with cok-

ing coal and fed into a coke oven where formed coke is produced and

charged into the blast furnace from the top.

4.3.4 Biochar

Biochar is a charcoal product of pyrolysis. Here, carbonization takes place at

relatively high temperatures. Biochar is known for its carbon sequestration

potential and soil remediation properties. Vegetation or forest residues are

often burnt down in some parts of the world for making room for cultivation

and to provide biochar to the soil that improves the fertility and other proper-

ties of the soil. An important aspect of this otherwise inefficient process is

that at least a part of the total carbon in biomass that would have been

released to the atmosphere as a greenhouse gas is now retained as

stable solid char in the soil. The higher the carbonization, the better is the

property of biochar though carbon retention as solid is less. It is discussed in

some further details in Section 5.8.

4.4 TORREFACTION PROCESS

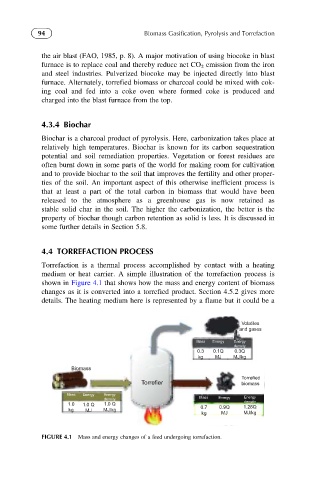

Torrefaction is a thermal process accomplished by contact with a heating

medium or heat carrier. A simple illustration of the torrefaction process is

shown in Figure 4.1 that shows how the mass and energy content of biomass

changes as it is converted into a torrefied product. Section 4.5.2 gives more

details. The heating medium here is represented by a flame but it could be a

Volatiles

and gases

Mass Energy Energy

density

0.3 0.1Q 0.3Q

kg MJ MJ/kg

Biomass

Torrefied

Torrefier biomass

Mass Energy Energy Energy

density Mass Energy

density

1.0 1.0 Q 1.0 Q 0.7 0.9Q 1.28Q

kg MJ MJ/kg

kg MJ MJ/kg

FIGURE 4.1 Mass and energy changes of a feed undergoing torrefaction.